Objectives of the service

SPECTRUM is a new analytical engine developed by DBX Commodities. This solution is catered for users across the steel industry and it offers a new way for monitoring the activity of heavy industrial sites. As the steel sector faces new challenges amidst the energy transition, SPECTRUM offers evidence-based analytics and via a set of carefully calibrated metrics, it assesses and predicts the status and activity rate of Blast Furnace and Steel Converters, plus many other production equipment elements within integrated steel plants. SPECTRUM observations and results are continually updated, as new visible and infrared images are collected in near-real time, but also produces estimates on longer time windows, fit for macro trend analysis.

Users and their needs

SPECTRUM addresses many of the pain points expressed by users and analysts within the broader iron ore and steel community, as well as some adjacent industries such as coal and maritime shipping. As they try to remove a veil of opacity from the supply chain and get hold of timely and precise information about raw material consumption, energy production, and physical production figures, they are usually stuck with lagging national statistics and customs declarations, rather than personal communication. SPECTRUM’s goals are tailored to alleviate this condition and usher the steel industry and market analytics to a new phase of data oriented analysis.

On release, the SPECTRUM product covers the whole European steel sector, monitoring all the active BF/BOF and EAF pig iron and steel producing factories, and as DBX expands to a new geographical region, the industry can expect to have access to the first Asian dataset very soon after release.

Service/ system concept

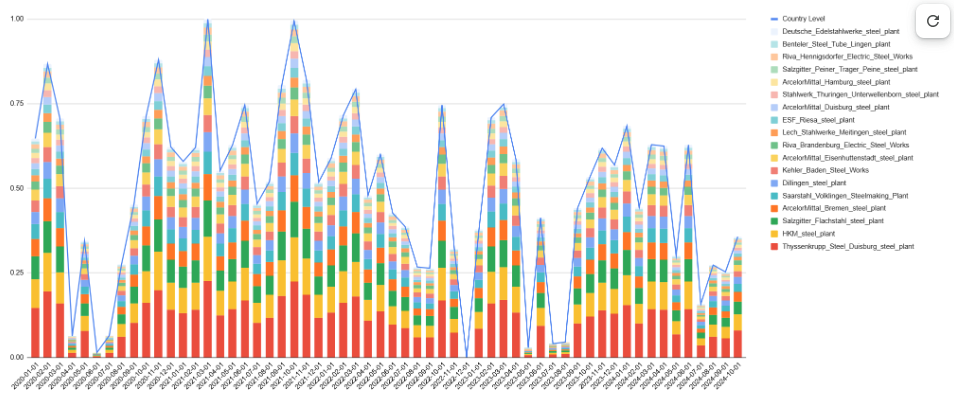

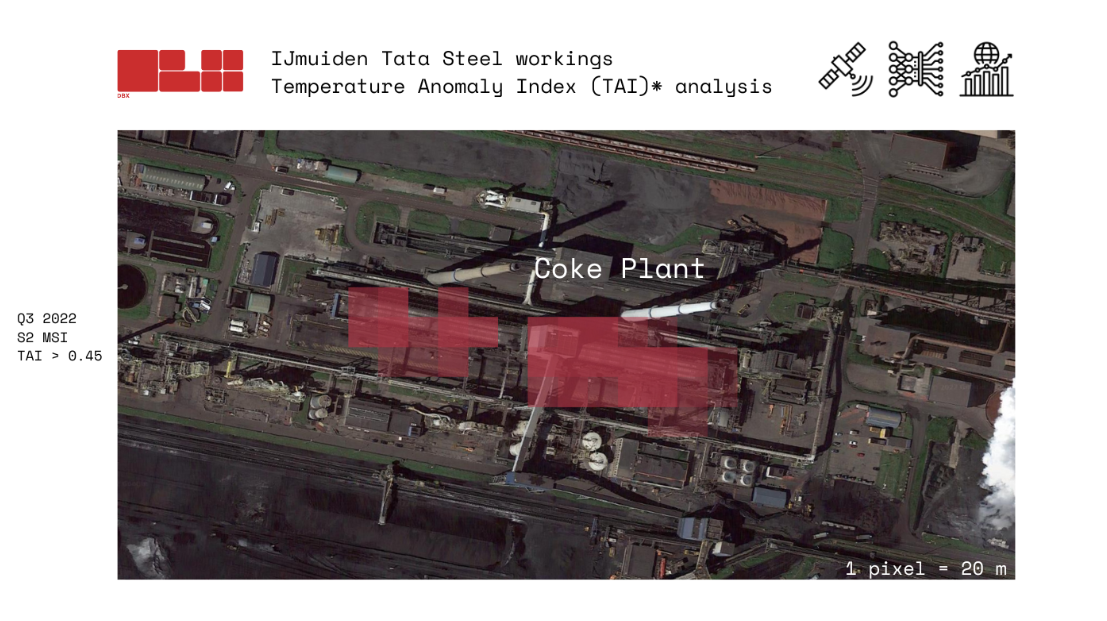

The information SPECTRUM provides to the users is a numerical, finely calibrated, characterisation of each steel plant. The most immediate and easy feature is to spot those factories’ activity status, whether they are in fact producing steel or not. But not just as a whole, but drilling down to sub-asset resolution, it provides to some extent a full tomography of the life of a steel mill. Typical sub-assets are Blast Furnaces, Blast Oxygen Furnaces, Coke Ovens, Sintering Plants, Flaring Stacks, finished product steel yards, slag pits and waste management facilities; for each of those items SPECTRUM defines a utilization rate and a status check (it checks if it is ON or OFF). It also includes a country level activity analysis, able to record and predict the future steel production figures, way faster than the national statistics and customs.

Space Added Value

The steel industry, as opposed to its sister sector, oil and gas, has a larger inertia and could not really follow the developments in technology, applied to measuring and estimating production and consumption of raw materials and critical metals.

With the use of open access Earth Observation missions, we try to lower the threshold for entering this space of market analytics, and open up to users and analysts that are traditionally not involved in data science oriented products. Sentinel missions in general offer an invaluable help for setting up semi continuous monitoring systems, especially the spectral range of MultiSpectralInstrument provides exceptional insights about the life of a steel mill.

Current Status

SPECTRUM is technically ready for a targeted launch, most of the roadmap targets have been satisfied and DBX is now ready for commercialization.

The SPECTRUM technology stack has been developed and tested against European case studies, showing maturity and accuracy in its predictions. DBX is entering a scale-up phase, including larger areas of geographical coverage, such as China, Hebei Province.

Approaching the Business Case Review SPECTRUM is able to define the status of steel mills with high accuracy at sub-asset resolution.

SPECTRUM is also able to produce estimates on a country level, aggregating all the activations processed in large countries and major producers like Germany or Spain.