Objectives of the service

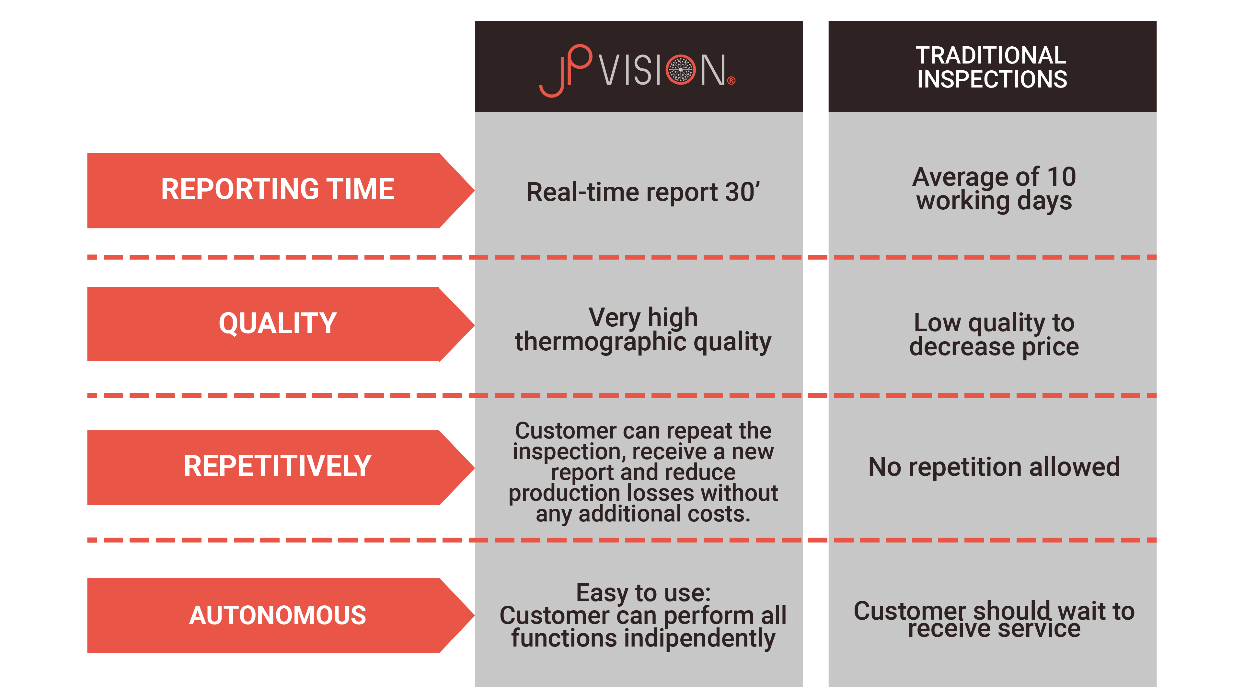

JP-VISION addresses the challenges of photovoltaic plant inspections by providing a fully automated, precise, and cost-effective monitoring solution. Traditional inspection methods are time-consuming, labour-intensive, and leading to inefficiencies in maintenance and energy production. The JP-VISION service integrates drones equipped with high-resolution thermal and multispectral sensors, combined with artificial intelligence for real-time data processing and anomaly detection.

This solution ensures accurate and repeatable inspections, delivering immediate insights through an online platform accessible from any location. Automated reporting allows operators to monitor system performance, detect faults early, and plan predictive maintenance, minimizing downtime and optimizing energy efficiency. The subscription-based model enables unlimited inspections without additional costs, offering continuous monitoring for long-term asset management.

The JP-VISION demonstration project focuses on refining the technology, expanding its applications, and integrating additional functionalities such as wind turbine and railway infrastructure monitoring.

Users and their needs

JP-VISION serves industries requiring precise and automated inspection of photovoltaic plants, with a focus on optimizing energy production and reducing maintenance costs. The primary user communities include photovoltaic plant operators, energy companies, maintenance service providers, and industrial asset managers across Europe, with initial applications in Italy. These users benefit from automated drone-based inspections that replace manual, labour-intensive monitoring processes.

Key user needs include:

-

Accurate fault detection - Identifying module defects, energy losses, and thermal anomalies to improve efficiency.

-

Automated and repeatable inspections - Ensuring standardized data collection without human intervention.

-

Real-time reporting and predictive maintenance - Reducing downtime and optimizing plant performance.

-

Cost reduction - Minimizing operational expenses by eliminating manual inspections.

-

Remote monitoring - Providing access to inspection data via an online platform accessible from any location.

Challenges include ensuring seamless integration with existing photovoltaic monitoring systems, optimizing AI-based anomaly detection, and refining automated reporting for better decision-making.

Service/ system concept

JP-VISION deploys to customers a fully automated thermal report for their PV (Photovoltaic) plants, including list of defects, strings problems or vegetation, including also a predictive analysis of the performances and losses. Data is collected directly from the customers, using drones and a flight APP that make everything automated. Data is then processed with an AI-driven software. JP-VISION also support the Serial Number reading of the PV modules.

Space Added Value

The JP-VISION service combines GNSS high precision RTK technology on drones, using AI and computer vision for a maximum precision level accuracy used for auto recognition of each single modules in a photovoltaic field. Satellite images are used at the beginning of the process to auto segment with AI the rows of the PV plants. GNSS RTK data are used during the flight, to guarantee precision of the flight and precision of the reference point of each picture acquired during the flight. Geo processing mixed with AI is used during the data process to combine position of each module to its serial number and thermal data. RTK precision is also mandatory for proper image stitching while producing reports. Correlation between real word position and image reference point is of paramount importance for an optimum level of service. Moreover, since RTK correction are normally under payment services and require extra hardware, in the project there is an evaluation of the use Galileo High accuracy service and PPP instead of RTK.

Current Status

The Demonstration Project has started in December 2024. JP Droni has already shown some basic demo to first potential customer during the KEY-ENERGY event fair held in March 2025 in Italy. User Needs, User Requirement and System requirements have been selected after some interview of the main stakeholders. System Architecture has been designed in a preliminary but consistent way and is implementing. Also web portal, flight app and DPS, which are the three main software components of the system, have a basic first version. Hardware setup and requirements have been defined, using DJI Enterprise drone series. The BDR (Baseline Design Review) milestone was reached in September 2025 and the team is now working on a design consolidation and some first tests. The next milestone is the CDR (Critical Design Review) and is expected to take place by November 2025