Objectives of the service

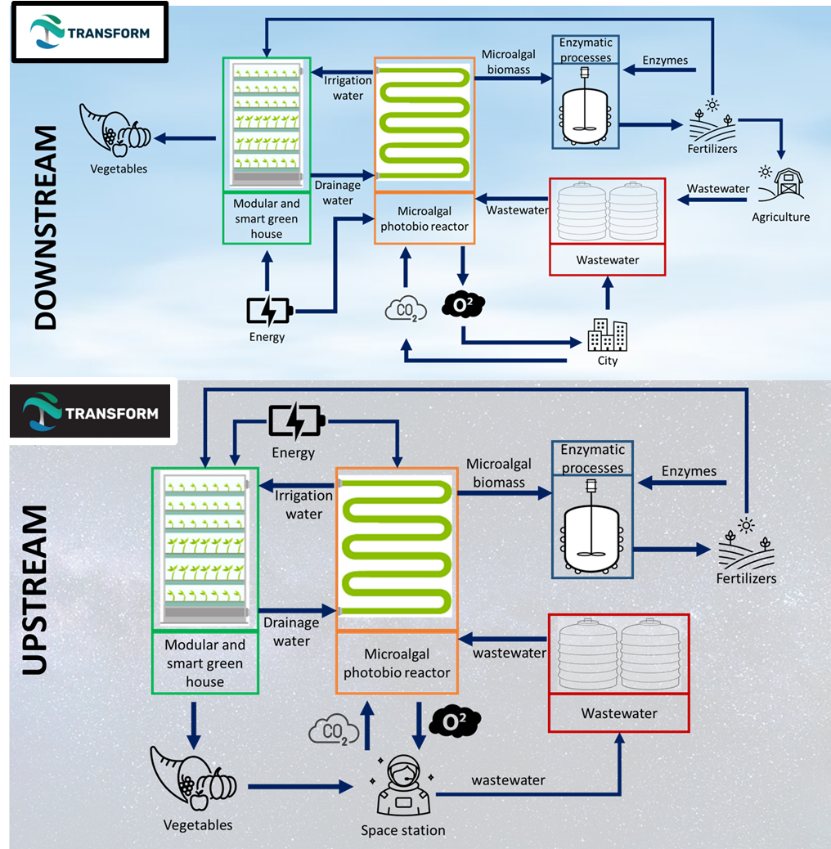

The TRANSFORM project addresses the pressing need for sustainable food production and resource recovery in both terrestrial and space-constrained environments. Users such as urban farmers, space station operators, and agritech companies face challenges related to land scarcity, high energy consumption, nutrient inefficiency, and the need for resilient, closed-loop cultivation systems. TRANSFORM offers a modular, automated greenhouse integrated with a microalgae-based wastewater treatment unit. This system maximizes crop yields by intelligently adapting shelf spacing to plant growth, reduces energy use through optimized lighting, and recycles nutrients and water via microalgae photobioreactors.

The activity focuses on validating the potential of this integrated solution to deliver a cost-effective and scalable cultivation system. It combines space technologies, originally developed for bioregenerative life support systems aboard spacecraft, with terrestrial applications in agriculture and wastewater management. Through market and technical assessments, stakeholder engagement, and a proof-of-concept study, TRANSFORM aims to lay the groundwork for future commercialization and service implementation both on Earth and in space missions.

Users and their needs

TRANSFORM targets professional users across the agriculture and space sectors in the wider European Union. The current user communities include vertical farm manufacturers, agricultural cooperatives, supermarkets, space station developers, and environmental engineering firms. These users share common challenges:

-

Reducing energy and water consumption in controlled-environment agriculture.

-

Increasing crop yields per unit volume in limited-space settings.

-

Minimizing reliance on chemical fertilizers through closed-loop nutrient systems.

-

Ensuring climate-resilient food production in urban or resource-scarce environments.

-

Deploying scalable and modular systems that are easy to operate and cost-effective.

Space sector users additionally require solutions that function reliably in constrained, isolated environments such as space stations, with low power demand and high regenerative efficiency.

The project must therefore deliver a system that integrates adaptive automation, microalgae wastewater treatment, and modularity while remaining economically viable and easy to maintain for non-expert operators. The key challenge is demonstrating this integration at a high level of technical readiness and economic attractiveness for diverse market segments. Target countries are European countries and US at this stage of the project.

Service/ system concept

TRANSFORM provides users with a fully automated cultivation system that combines a vertical greenhouse and a microalgae based water treatment unit. The system enables users to produce vegetables, fruits, and leafy greens while recycling water and generating natural fertilizers on-site. It supplies real-time data on plant growth, environmental conditions, water quality, and nutrient levels through integrated sensors and a user-friendly control interface.

The greenhouse features adjustable shelves that match plant growth, maximizing space and light efficiency. Below the greenhouse, a microalgae photobioreactor treats wastewater from the cultivation process, removing contaminants and converting nutrients into biofertilizer. The cleaned water is then reused for irrigation, creating a circular system.

From a high-level perspective, the system is made up of four main components:

-

Modular Adaptive Greenhouse: with moving shelves and automated climate control.

-

Microalgae Photobioreactor: treating wastewater and capturing nutrients.

-

Fertilizer Reactor: converting harvested algae into biofertilizers.

-

Monitoring & Control Unit: managing sensors, actuators, and data dashboards.

Together, these components allow users to grow more with less: higher yields in a smaller footprint, reduced energy and water consumption, and near-zero waste operations on Earth or in orbit.

Space Added Value

TRANSFORM leverages human spaceflight technologies, particularly adaptive greenhouse systems and photobioreactors originally developed for life support in space missions. These technologies have been optimized for closed-loop resource management, maximizing productivity in minimal space, recycling water and CO₂, and enabling autonomous operation. By transferring these innovations to Earth-based applications, TRANSFORM provides key advantages over conventional vertical farms. The adaptive shelving system, inspired by space constraints, allows dynamic reallocation of volume based on plant growth, significantly increasing yield per cubic meter. Meanwhile, the microalgae photobioreactor—originally tested aboard the International Space Station, purifies wastewater and produces oxygen and biofertilizers, reducing the need for external inputs. Unlike traditional greenhouses and fixed-shelf vertical farms, which often suffer from high energy costs and inefficient use of space, TRANSFORM integrates proven space methodologies for superior efficiency. This unique space-to-Earth transfer enables the creation of a scalable, modular, and sustainable food production system with minimal environmental impact and enhanced self-sufficiency, critical for both urban farming and extreme environments.

Current Status

The TRANSFORM project is advancing through its initial implementation phase. Engagement with stakeholders from the agriculture, space engineering, and biotechnology sectors has begun, supported by a targeted survey collecting technical and commercial inputs. Participation in national events has enabled early outreach to potential pilot users and investors. Work is ongoing to define the integrated architecture of the adaptive greenhouse and microalgae treatment systems, focusing on modularity, automation, and resource efficiency. A preliminary business plan has been outlined, including market sizing, revenue projections, and investment requirements for both terrestrial and space-related applications. Alignment with space system requirements is being pursued through discussions with stakeholders active in orbital infrastructure and life-support systems. Upcoming tasks include system concept validation, refinement of user-driven KPIs, and preparation of a roadmap for future service rollout and demonstration activities under ESA’s Business Applications framework.