What happens near a black hole? How does ordinary matter come together in the large-scale structures we see today? How do black holes grow and shape the universe and what is the relationship between these processes?

All these questions will be answered very soon by the Athena advanced telescope for high-energy astrophysics. “Athena will be a state-of-the-art observatory that will provide a significant leap forward in scientific capabilities compared with previous X-ray missions, and will address fundamental open questions in astrophysics,” says Alvaro Giménez, Director of Science and Robotic Exploration at the European Space Agency (ESA).

Austrian RHP Technology GmbH stands ready to contribute to ESA’s second ‘Large-class’ science mission. A total of six test parts have already been manufactured, which RHP Technology GmbH conducted in cooperation with AAC Aerospace and Advanced Composites and FOTEC Forschungs-und Technologietransfer GmbH.

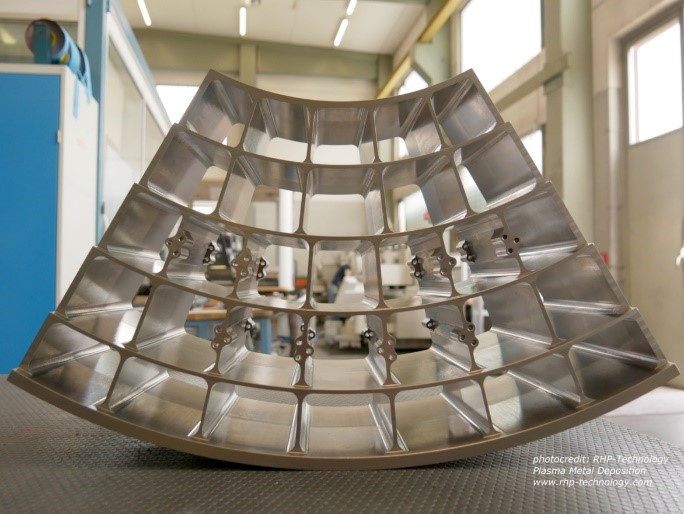

The prototype is a 3D-printed and partly processed version of what may someday become the ‘eye’ of the ESA X-ray telescope Athena. This test structure was produced by an ESA-led 3D project to evaluate a promising method called ‘Plasma Metal Deposition’.

“The project’s goal was to evaluate the technology’s ability to produce space hardware and components larger than 0.5m,” explains ESA materials engineer Laurent Pambaguian. Dr. Erich Neubauer, Managing Director & Owner of RHP Technology GmbH says: “More than 80% of material is wasted by using a traditional method of manufacturing; which is typically milling from a block. By using our Plasma Metal Deposition technology, we were able to demonstrate a significant material and cost saving”.

“We examined the entire process chain, including subsequent heat treatment and post-processing, as well as 3D printing, using titanium alloys either as metal particles or as wire material. The result has demonstrated good mechanical properties and finishing, signifying that we are capable to advance the technology, including the investigation of alternative materials.”

Plasma metal deposition is a candidate for manufacturing large-scale components in the future, such as the Athena mission optical bench, which will be the most complex part ever printed in titanium.

In a complex structure with many deep pockets tapering to a maximum height of 30 cm, the optical bench aligns and secures around 750 mirror modules. The overall shape must be accurate to within a few ten micrometers – or thousandths of a centimetre. “RHP demonstrated that large 3D parts can be printed for space applications. In the future this technology can be used for applications on Earth such as industrial, aeronautics or automotive applications,” says Susanne Katzler Fuchs from Brimatech, the Technology Transfer Broker for ESA Space Solutions in Austria.

When ESA's Athena satellite is launched in 2031, it will be 10-100 times deeper than in previous X-ray missions to observe the hottest, high-energy celestial objects.

ABOUT ESA SPACE SOLUTIONS

ESA Space Solutions is the go to place for great business ideas involving space in all areas of society and economy. Our mission is to support entrepreneurs in Europe in the development of business using satellite applications and space technology to improve everyday life. ESA Space Solutions is designed to provide multiple entry points such as ESA Business Incubation Centres (ESA BICs), ESA Technology Broker Network, ESA Business Applications Ambassadors and ESA Business Applications programme. Funding typically ranges from €50k to €2M and supports everything from technology transfer, business incubation, Feasibility Studies to large-scale Demonstration Projects.