Objectives of the service

European rail systems need to increase their transport capacity of persons and goods, reducing costs caused by trackside equipment, and in parallel unifying different national regulations, while maintaining the high level of safety. For this purpose the Level 3 of the European Train Management System (ERTMS) standardises the necessary components and regulations. The capacity increase shall be achieved by the transition from train management by trackside fixed blocks to fixed virtual blocks or moving blocks. One essential element is the continuous monitoring of the completeness of a train (“train integrity”) without the need of trackside equipment. Technical solutions exist – except for freight trains, because their wagons do not provide an electrical power supply.

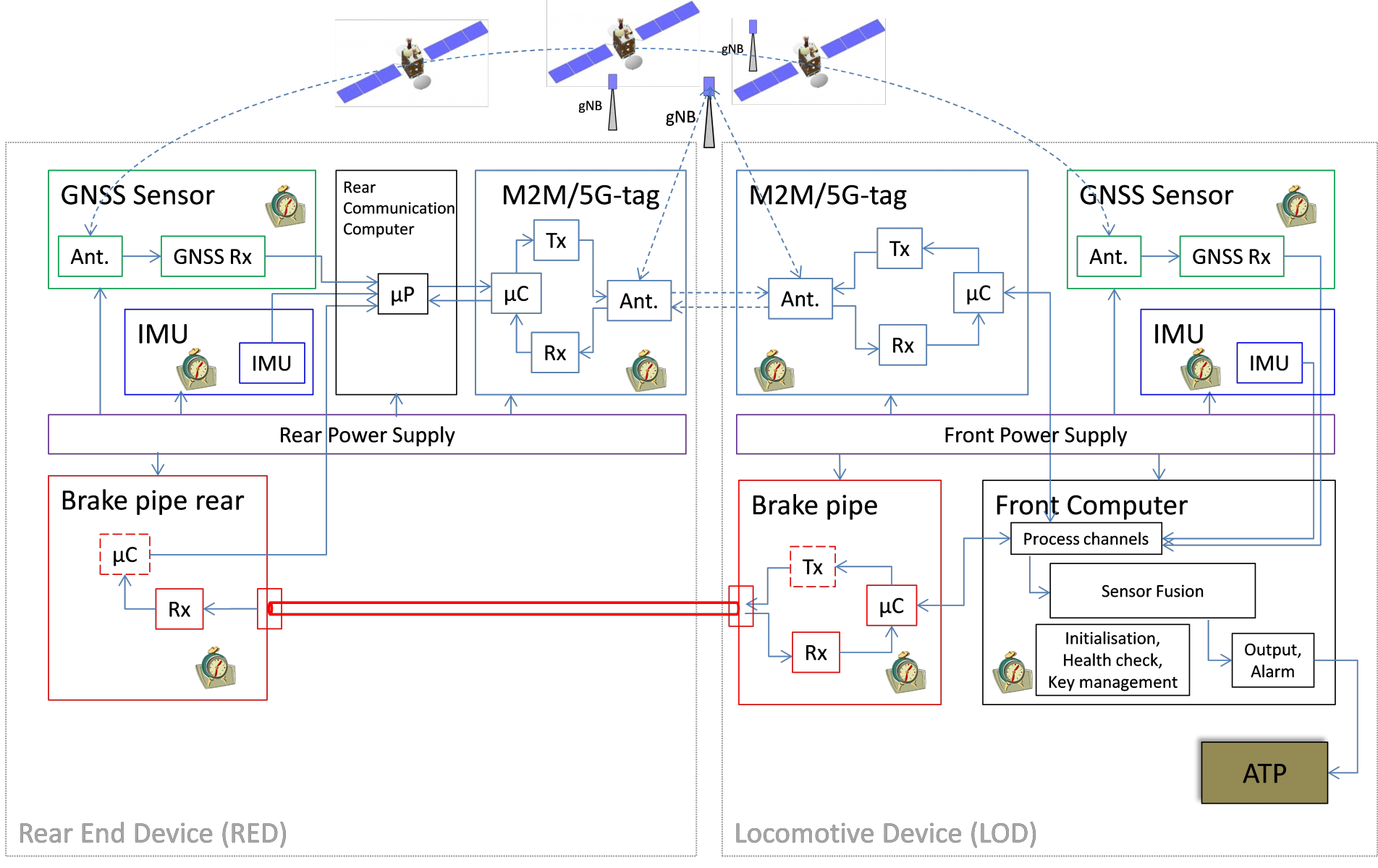

The project “3TIMS” focusses on three technologies (GNSS, IMU, Brake Pipe monitoring) plus M2M radio link to close that gap.

Starting from an analysis of the stakeholders’ and users’ technical and economic needs 3TIMS establishes the user- and system requirements for an on-board train integrity monitoring system (TIMS) for freight trains, and assesses the suitability of the three candidate technologies. On this basis, the design is elaborated, complemented by an extensive Functional Analysis, Hazard Analysis, FMECA and Fault Tree Analyses, and consolidated by a proof-of-concept analysis complemented by an economic viability analysis to consolidate the concept.

Users and their needs

The primary users of a freight train integrity monitoring system are the railway undertakings and infrastructure managers in Europe or worldwide, like e.g. DB (Germany), SNCF (France), RFI (Italy). Within those organisations, shunters (ease of installation), maintainers (ease of use/maintenance), train driver (initialisation and operation), train managers (required safety level and availability of train integrity information, seamless integration into established workflows) are further stake holders. Apart from the high safety and availability level, railway undertakings and infrastructure managers are also interested in a cost-efficient device throughout its lifecycle (procurement, installation, operation, maintenance, decommissioning).

Targeted users are railway undertakings and infrastructure managers in Belgium, Denmark, France, Germany, Italy, Norway, Spain, Sweden, Switzerland, The Netherlands, United Kingdom (ERTMS users group), but also in Africa, America, Asia, Australia.

Service/ system concept

The train integrity monitoring is a function within the ERTMS Level 3 system. With absolute positioning of trains it would be possible to reduce the separation of the trains down to the distance to complete stop, plus length of the train, plus a safety margin. Therefore, the on-board Train Integrity Monitoring System (TIMS) must continuously monitor the length of the train and report/alert status, length, and margin to the ATP using a defined set of variables. The ATP calculates the safe train length from the distance between safe rear end at last train integrity measurement time to the safe train front at time of reporting which includes a margin for clock synchronisation and residual positioning errors.

Use of GNSS benefits from differential positioning, but needs to be augmented by inertial navigation in tunnels and poor satellite visibility conditions as well by further train integrity sensors to ensure the safety and availability level (SIL4) required in rail operation also under a multitude of adverse environmental conditions.

The 3TIMS project elaborates for freight trains a sensor fusion of IMUs, GNSS receivers at train head and end, plus monitoring of brake pipe pressure variations and investigates the use of two-way time transfer between a pair of M2M tags. In addition, a radio-link from train end to head (e.g. by use of M2M/5G tags) and a power supply unit are necessary, see the following diagram.

Space Added Value

Because the train localisation and integrity monitoring is needed for large areas (country- and continent-wide) a terrestrial solution would need a very high number of stations (e.g. GBAS or geodetic networks) with implied cost of operation and electricity.

Being radio links, additional security by encryption and authentication, e.g. as provided by Galileo (commercial or even public regulated services), are of interest, depending on related costs.

In addition, 3TIMS investigates the use of M2M tags that could be observed from space (e.g. similar to Icarus), using adequate IoT payloads. That would help to localise separated or ‘lost’ wagons.

Current Status

The 3TIMS project collected the User & Stakeholder needs and performed the assessment of the three targeted technologies (GNSS, IMU, Brake Pipe Monitoring), plus M2M for the data link between train end to -head and its use for a distance measurement. The requirements review was passed in July 2019, and the System and Service Definition Review in December 2019. The proof-of-concept phase and viability analysis were successfully finished and the Final Review was completed in April 2020.

The overall result is that a Train Integrity Monitoring Device involving all three technologies combined by a sensor fusion function is technically, operationally and economically feasible, although a number of operational and technical aspects need to be further consolidated by operation and measurements in a real environment.