Objectives of the service

Image credit: Project Consulting s.r.l., Project: AIDA-SHM

AIDA-SHM (Artificial Intelligence Data Analyser – Structural Health Monitoring) is a turnkey system to monitor the health of structures such as bridges and viaducts, predict possible structural damage events and enable optimization of preventive maintenance so to reduce the costs of highly specialised personnel.

AIDA-SHM uses powerful artificial intelligence algorithms capable of extracting information from data and events. AIDA-SHM AI Engine analyse data and discovers associations, correlations and trend between data and events and defines model representative of the structures evolution and deterioration; it deeply differs from statistical analysis paradigm, which defines probabilistic models based solely on the events' frequency.

The strong innovation in AIDA-SHM solution consists in using simultaneously the technique of passive acoustic emission, the analysis of signals and parameters through an automatic learning engine (Artificial Intelligence - AI) and the connection of sensors through a satellite IoT network.

Users and their needs

The health assessment of bridges and viaducts is an urgent matter. The number of works built in reinforced concrete after the war is very high: many of these works are aging and are close to the end of their life cycle. Specific quality standards (ref.: UNI/TR 11634:2016) have been defined to guarantee the correct installation and maintenance of concrete structures, reinforced or pre-stressed, and avoid sudden collapses and damage to people and property. AIDA-SHM users are Road and Highway management companies and builders of large structures, such as bridges and viaducts. The main needs of these users are: monitoring aging damages, improving maintenance effectiveness in terms of planning and cost reduction, reducing risks, fast and accurate location of the point of failure, on time prediction of possible failure.

Service/ system concept

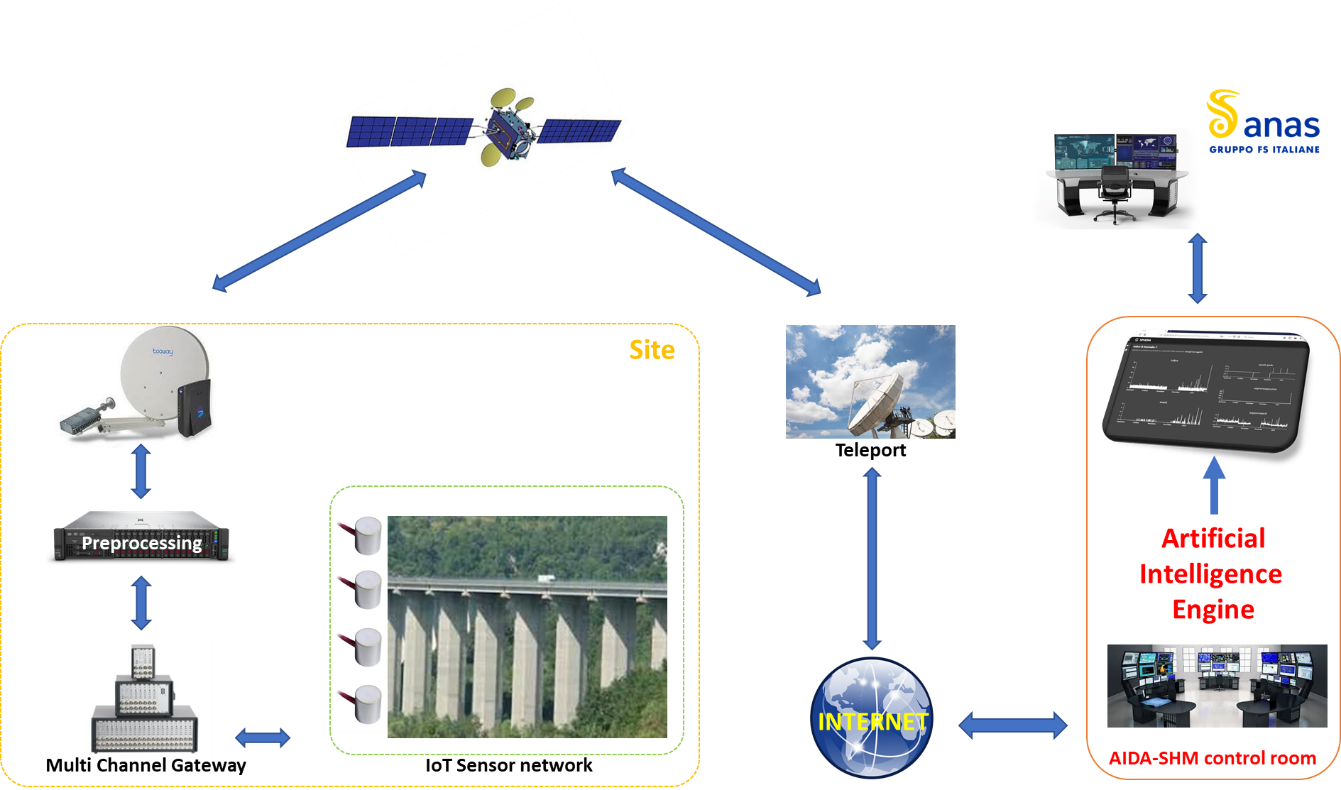

Image credit: Project Consulting, Project: AIDA-SHM

The system evaluates continuously the content of the signals coming from a network of sensors (e.g. Acoustic Emission sensors and other parametric sensors such as temperature, accelerometer, strength gauge), compares them with the historical ones acquired in a "long" window that is sufficient to identify structural changes. After a training phase for the AI engine, AIDA-SHM is able to "learn" the dynamics of the signals coming from sensors installed on the structure: every time a signal deviates from its "nominal" range, an anomaly message will be generated. Whenever the system detects a signal related to the occurrence of a possible damage (e.g. formation of a crack, detachment of the steel from the cement, presence of unforeseen structural discontinuity, corrosion) an alarm signal is generated which is memorized and submitted to the attention of the users/operators, so to help them defining the most appropriate and timely maintenance activities.

Space Added Value

It would be very expensive to use terrestrial technologies to guarantee the connection along the entire highway network, in order to ensure the positioning of the sensors in the most strategic points of viaducts and bridges, linked to the structural morphology.

The use of satellite connection in an IoT network architecture enables to cover the entire territory and is able to guarantee the service levels and the bandwidth required for the real-time collection and transfer of data, allowing so monitor bridges, viaducts, dams, without constraints and positioning limits.

Current Status

The project started on March 2, 2020 and has passed the Baseline Design Review (BDR) in April 2020. In October 2020 successfully passed the Factory Acceptance Test (FAT). In the spring 2021 the site was prepared, the hardware and software components were installed, and on May 17 the system began acquiring data from the site. The Site Acceptance Test (SAT) was successfully carried out on July; after having trained ANAS staff dedicated to AIDA-SHM, the Pilot phase officially began on July and has been completed on October 2021.

The FR has successfully concluded in November 2021.