Objectives of the service

Over the last 4 years, the share of solar in the energy mix has increased 200% in Europe and it will grow 4 times more by 2030, reaching the 8 TW solar capacity. To meet this growing demand, solar parks are becoming larger and more remote. Although solar panel technology is getting more reliable, preventative inspections are required at least once a year to ensure peak performance. Thus, inspections of vast solar parks are time-consuming, precisely locating a single broken panel is a real challenge and with millions of new panels added yearly, inspection costs keep rising. These challenges are calling for new robotic solutions to automate inspection and maintenance processes.

The objective of the Autonomous Navigation for more Efficient Solar Inspection (ANESI) service is to reduce operational time during inspections, precisely locate anomalies in the solar panels and reduce the associated costs. ANESI avoids the use of manual visual supervision and adjustments of flight paths. Autonomous navigation based on advanced computer vision ensures that the target remains within the camera frame, with no pilot assistance. The use of Vertical Take-Off and Landing (VTOL) Unmanned Aerial Systems (UAS) allows to fly for longer period than multirotor drones (4 hours vs 30 minutes). Through large flight endurance, Aerial Tools VTOL UAS can cover an area 50 times larger than competitors. Combined with Real Time Kinematics. Global Navigation Satellite Systems (RTK GNSS) positioning, problematic modules are precisely allocated. This huge improvement in speed can reduce inspection costs by up to 60%.

Using ANESI, operators can access efficient and actionable inspection data through an interactive web portal to manage their solar assets and simply plant management.

Users and their needs

ANESI targets the solar energy sector in Europe. More specifically, ANESI targets large solar energy companies that operate, and/or own solar parks. These companies are required and have allocated budget to perform periodic and preventive inspections of their parks with aerial thermography once or twice a year. They have understood the potential of aerial inspections using drones to evaluate the performance of the solar panels. Their main need is to have high-quality anomalies detection to increase efficiency, but with reduced operation time and costs.

Consultancy and certification companies can also benefit from ANESI as they are subcontracted by energy companies to certify the state of the park. They usually perform reactive maintenance, which refers to addressing an issue when it arises instead of regular scheduled maintenance. They also focus on measuring the park performance during commissioning to ensure that the park is operating at its peak performance level. These usually occur during traits and insurance claims. Such operations require therefore to be fast. In addition, they are very eager to find innovative technologies and autonomous systems that avoid manual assistance.

Othe inspection companies in charge of monitoring solar farms can also be users of the ANESI service as they often face limited resources (manpower, time, budget) to deal with large and remote solar parks.

Service/ system concept

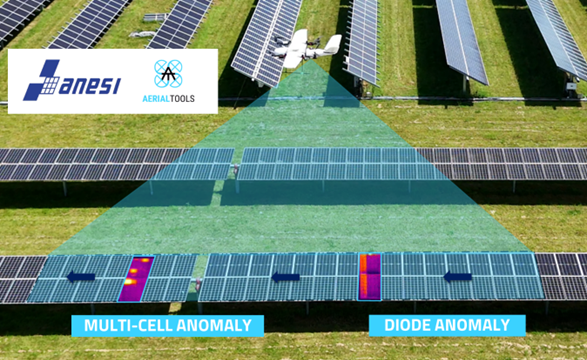

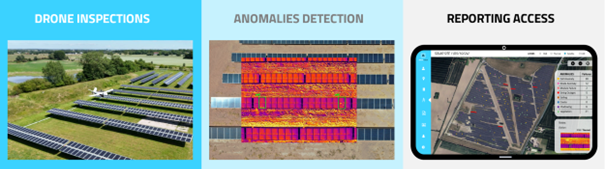

ANESI offers a comprehensive, end-to-end service designed to support solar parks inspections with precision and efficiency. This service encompasses all stages, from drone inspections and data acquisition to anomalies detection using machine learning, and reporting access.

Aerial Tools ApS has developed a VTOL UAS capable of inspecting up to 800 ha/day. The UAS is equipped with a dual RGB/IR camera and RTK GNSS antenna for high precision and accuracy of anomalies detection. Combined with advanced computer vision algorithms, the UAS enables autonomous flight and automatically adjusts its path in real-time to ensure optimal data acquisition. This is achieved through the patented plug-and-play payload system.

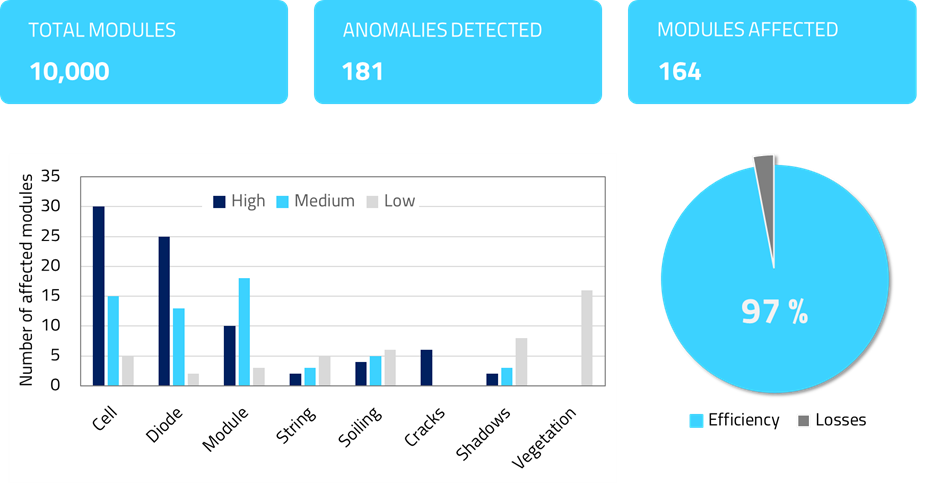

The collected data undergoes in-depth analysis through the anomaly detection software, which identifies, classify and geolocates the anomalies. The end user receives a comprehensive report detailing all identified anomalies and its precise location within the solar panels. The report includes both tabular data and technical drawings for enhanced visualization, accompanied by a general energy efficiency assessment to provide clients with updated solar farm status. The service can also deliver a digital twin of the solar park, offering an immersive and detailed representation alongside the standard inspection reports.

Space Added Value

ANESI requires high-precision UAS positioning and timing during data acquisition. Currently, the system employs an RTK GNSS while complying to visual line-of-sight (VLOS) flight regulations. Additionally, to reduce the risk of communication loss between the pilot and the UAS, 5G SatCom technology has been implemented. The integration of 5G also eases data transfer between the UAS and company servers, enabling real-time mission status updates and enhancing overall operational efficiency.

Satellite Earth Observation (EO) information is used by the ground control station to automatize initial path planning, investigate customer-requested areas and to compare the results from the inspections, facilitating the creation of 2D maps.

Current Status

The ANESI Project was conducted from May until December 2024. All technologies are fully operational and integrated into a testing UAS platform. Autonomous navigation and computer vision algorithms have been successfully simulated in a virtual environment, using an alternative airframe and ground control software.

Following successful results, the airframe model has been upgraded to the company’s airframe, and integration with the company’s ground control software is in progress. The anomaly detection software has been tested with real data from a customer, performing as expected, detecting and classifying thermal anomalies.

The perspectives of Aerial Tools are to continue developing tailored solutions for improving inspections of solar parks and reach to market in 2025.