Objectives of the service

The solar photovoltaic energy market is showing an ever-increasing demand in the last years, with ongoing focus on scaling up the world’s renewable energy generation capacity. This significant growth of the photovoltaic solar market has two main consequences: 1) the increase in the number of installations and 2) the increase in the average size of said installations.

This growth generates a need to correspondingly scale up the sector’s capability perform regular asset inspections to detect and repair faults in solar cells and modules in a timely manner, to keep the installation working at high capacity. UAV-based thermographic inspection is an optimal way to perform full plant inspections, detecting faults early and determining their underlying causes. However, this process generates huge amounts of data, and the manual execution of this analysis, as it is mostly done to date, has serious disadvantages for customers mainly due to the following two aspects:

-

Time-consuming activity: leading to significant delays between contracting and receipt of inspection results, and in turn infrequent inspection scheduling: installations will be left operating below maximum performance for extended periods.

-

Manual, tedious and repetitive tasks: leads to a cumulative increase in the probability of mistakes due to human fatigue, making it difficult to scale to large photovoltaic installations.

This scenario calls for the development of means and procedures that optimize the thermographic data processing, with the consequent reduction in time, thanks to a high level of automation, the elimination of the human error factor, and delivering the accuracy of cutting-edge AI and computer vision techniques.

Users and their needs

Our analytics-as-a-service tool is aimed at thermographic inspection companies that serve the main stakeholders of the photovoltaic sector: Engineering, Procurement and Construction (EPC) companies, PV asset owners, Operation & Maintenance (O&M) companies, etc.

These inspection companies organise the UAV flights to acquire the required data, either with own UAVs or through partner pilots, and provide detailed inspection reports to their customers. Most of these companies lack the capability to analyse the thermographic data on their own, as they either focus on UAV flights or are too small to afford building their own capabilities. The main needs of our customers are the following:

-

Low-cost, automated, and quick analysis of thermographic data and reporting of results.

-

Precise fault detection, identification, and location.

-

Robust inspections against false positives.

This collection of needs is the ideal scenario for an AI-based solution, which can process large amounts of data in short times, at low cost, and eliminating human errors.

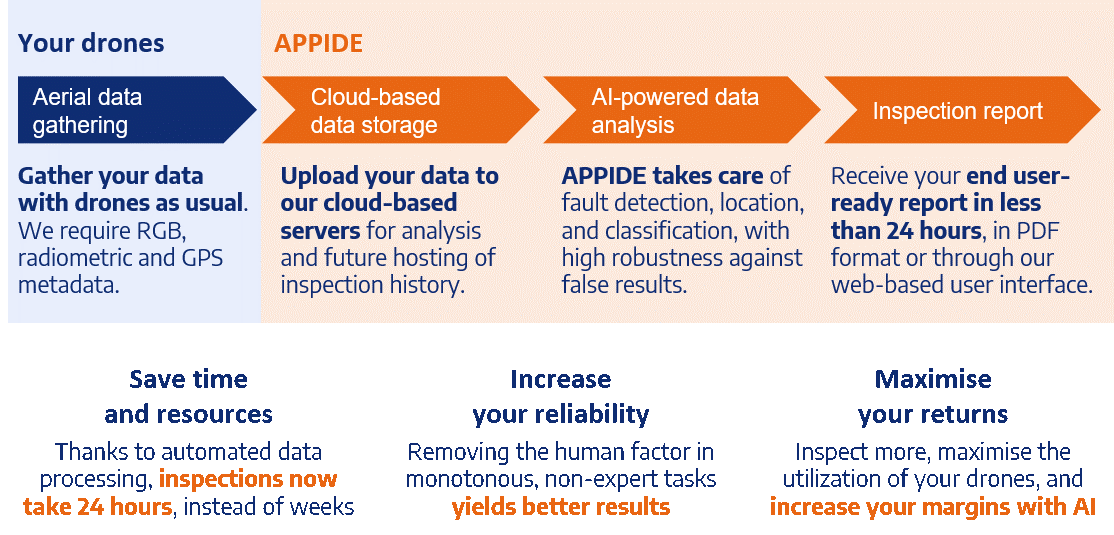

Service/ system concept

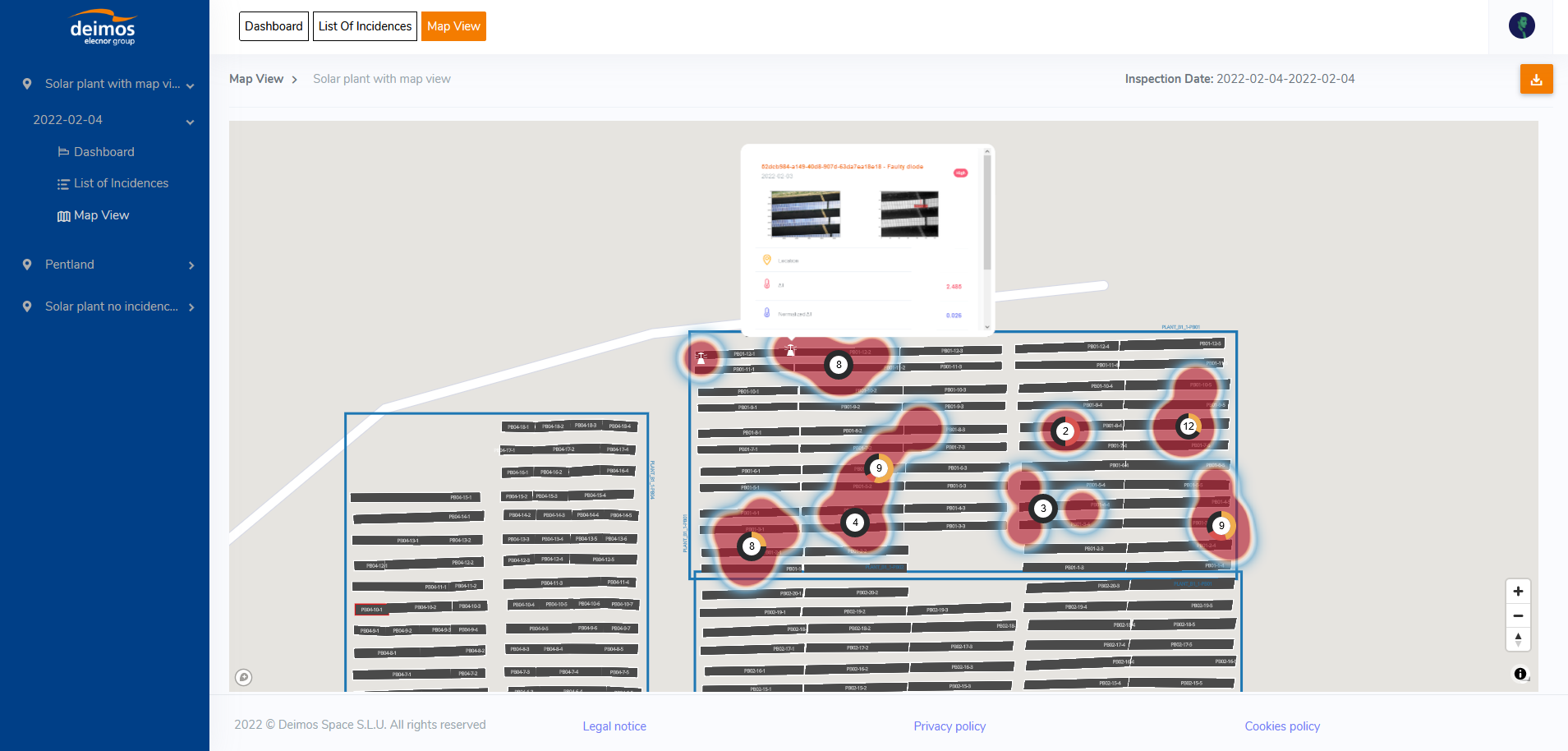

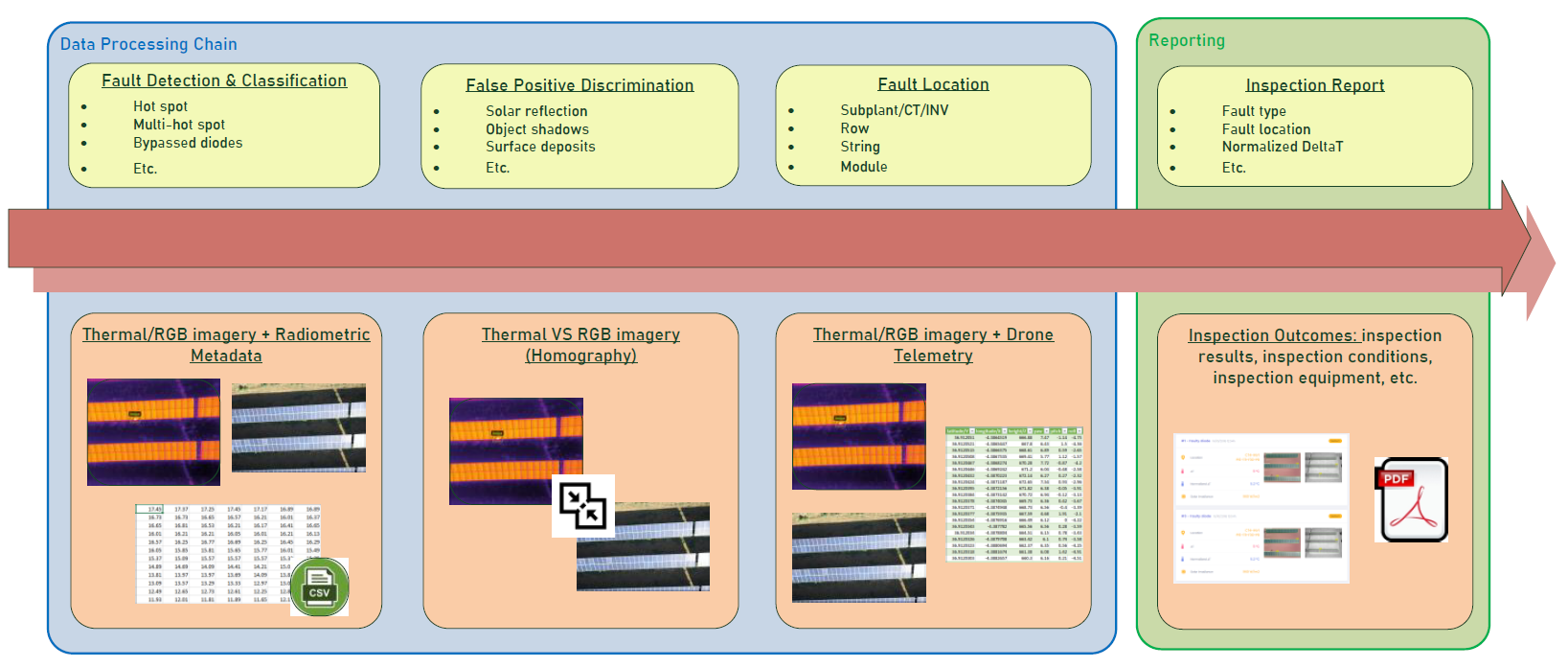

Our data-analysis service uses thermographic and RGB imagery of solar plants to detect electrical faults in solar panels. The data is provided by the thermographic inspectors, and they receive a detailed inspection report (in digital and PDF format) as output. The report contains information on the faults or incidents found in the cells, modules, and strings of the PV asset. This information is crucial for PV plant owners to maintain the efficiency of their plant, which is the main goal of thermographic inspections.

Thanks to automatic data processing, we can generate large amounts of insights for each inspection, at a lower cost. This allows thermographic inspectors to fly their drones more often, maximising their return on investment, as well as PV plant owners to perform more comprehensive, recurrent inspections, maximising the efficiency of solar assets. Our web-based user interface allows our users to process the data from all inspections more easily than with traditional PDF reports.

To achieve all of the above, it is necessary to process the input data properly through our automated tool. The processing chain for this tool is briefly explained below:

-

Fault detection & classification: images captured with the UAV will be processed and analysed using artificial intelligence algorithms, to detect and classify faults.

-

False positive discrimination: multispectral imagery data fusion will be used, using RGB cameras to discriminate false positive detections and unambiguously determine the underlying root cause of real faults.

-

Fault location: through navigation and positioning techniques combined with asset detection and computer vision analysis, the position of each detected fault within the wider installation will be identified. This also provides an “on-the-fly” model-free asset digitisation service without the need to perform high-altitude overview flights.

Space Added Value

As a key aspect, our service leverages Satellite Earth Observation and Satellite Navigation space assets. In this way, we can offer our customer an effective, efficient, and accurate solution providing extended information on the status and performance of their facilities.

On one hand, the use of Satellite Earth Observation allows us to carry out an adequate flight planning and, thanks to the very high resolution (VHR) images, it permits us to analyse the status of the plant to verify that it is ready to be inspected (for example, detecting and monitoring the presence of obstacles, vegetation in excess, status of installation cleanliness, etc.). We also leverage our image processing algorithms, developed for space, as a key element of the processing chain.

On the other hand, the use of Satellite Navigation allows us UAV operators to execute precise flights, and enables our AI to accurately locate the detected faults at solar module level, integrating the navigation solution in our algorithms.

Current Status

We performed several pilots to obtain essential input from customers. to confirm the end-to-end product performance and market fit. This goal was achieved, as the seven performed pilots provided detailed insights on APPIDE’s current competitive advantages in the market, as well as its shortcomings that may prevent its market penetration. The pilots led to our first commercial customer and sale, as well as generating a pipeline of potential customers and partners. We continue to use of the pilot scheme as a “free trial” for potential customers, as customers that performed a pilot typically show interest in working with APPIDE in the future.

The final review meeting was held on the 27th of July 2023. A CCN to the project is currently under review, to support the implementation of key user-driven feature updates identified from the pilot phase, necessary to maximise product market reach.