Objectives of the service

The growing demand for food and energy security, coupled with decreasing availability of arable land due to global population growth and land use for energy production, presents a major challenge for societies aiming to transition towards a low-carbon and green economy. Agri-PV is a promising solution as it integrates energy production and agriculture in a single system. However, this co-location presents numerous challenges for Agri-PV stakeholders, which must be understood to ensure the sustainability of Agri-PV plants.

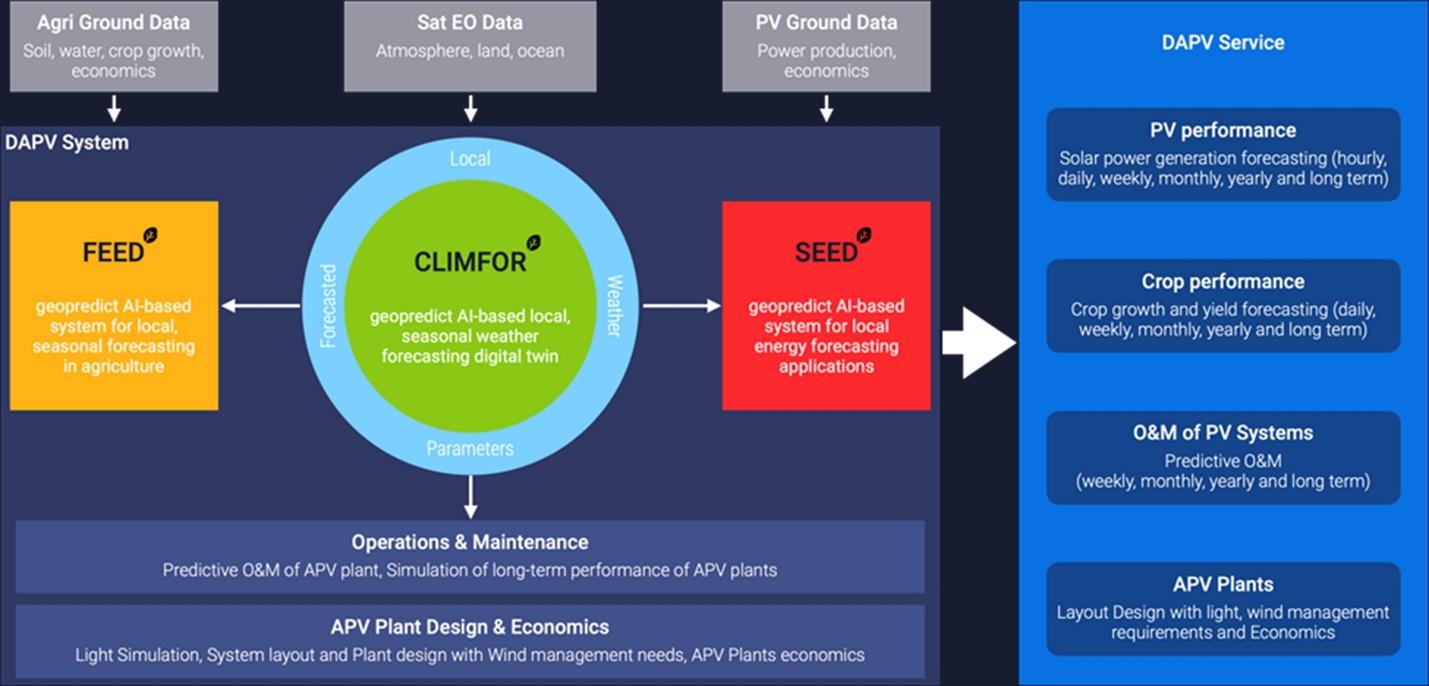

DAPV stands for the Digitalization of Agri-Photovoltaics forecasting system using Earth Observation and Ground Data. The goal of DAPV services is to provide a unique, integrated solution for various segments of Agri-PV customers. This solution leverages innovative, self-learning AI technologies to forecast weather and climate, energy generation, crop yield, operations and maintenance, plant design, and the economics of Agri-PV systems. It utilizes both satellite Earth observation data and actual ground data.

The main objectives of the DAPV feasibility study is to: engage with Agri-PV customers and users to understand their requirements; design the DAPV architecture based on these requirements; assess the technical feasibility of the DAPV services, including developing a proof-of-concept at the APV pilot customer sites; and consolidate the findings into a study on technical and commercial viability, culminating in a roadmap for the service market roll-out.

Users and their needs

This study is aimed at understanding the challenges faced in three important customer segments in Agri-PV:

-

Energy companies

-

Agri-PV developers and EPC companies

-

Large farmland owners as well as farmers

Following is the summary of important desires and requirements from most of these customers:

-

Integrated Monitoring and Forecasting System: A comprehensive system for monitoring and forecasting in Agri-PV, that can provide real time updates as well as location-specific weather forecasts and the ability to accurately predict energy generation, crop yield, predictive operations and maintenance (O&M), and revenues (economics).

-

Design Optimization: The ability to optimize APV system design at the planning stage using inputs from satellite Earth observation and AI technologies.

-

Regulatory Compliance: Services should adhere to relevant regulations, considering either crop yield optimization first or a balance between crop and energy production optimizations during the planning and design phase of APV systems.

-

Pre-Design Estimations: A need exists for pre-design estimations and predictions regarding the size, design, and performance of the APV system, including energy production, crop growth, and O&M losses. Currently, no such systems are available for APV, making DAPV services highly desirable.

-

Site Characteristics Analysis: Evaluation of APV site characteristics, such as soil quality and water resources, before and after construction using satellite Earth observation data.

Service/ system concept

The DAPV service concept aims to provide a location-specific, intelligent decision support system that forecasts energy, crop growth, and O&M (from days to years in advance) for the Agri-Photovoltaic (APV) sector. This system, including plant design services, is tailored to support planning, development, economics, and operations. Leveraging space-based earth observation (EO) data and on-site PV and agricultural data, the disruptive deep-learning AI technology will deliver accurate forecasts based on APV location weather to farmland owners, APV plant designers, planners, energy companies, agriculture and food companies, and the public.

Space Added Value

The DAPV services will extensively rely on satellite earth observation as the primary source of information for atmosphere, energy resources, crop growth, APV plant design, and O&M, modelling, and forecasting. It will utilize atmosphere (surface and pressure level), selected ocean surface data, and land data based on COPERNICUS (CAMS, C3S, CMEMS, CLMS, SENTINEL) services, as well as EUMETSAT, ECMWF, and NASA datasets at different spatial and temporal resolutions.

Traditionally, modelling, forecasting, and decision-making in renewable energy and agricultural applications have relied primarily on in-situ ground data. However, the spatial resolution, data quality, and availability of this data can vary significantly across regions and among different energy or agricultural farm owners. Given the co-location of energy and agriculture in Agri-PV (APV) systems, similar challenges are expected. The inconsistency of ground data complicates the development of a generalized AI-based approach for modelling, forecasting, and decision-making.

In contrast, satellite Earth Observation (SatEO) data provide consistent parameters, spatial and temporal resolution, and data quality worldwide. This consistency enables the creation of innovative AI-based business models that are flexible, adaptable, reliable, accurate, transparent, and trustworthy. Our experience in renewable energy forecasting has shown that using SatEO data can increase economic value by up to 50% compared to other methods.

Current Status

The DAPV feasibility study, conducted at two Agri-PV customer sites in the EU, was successfully completed. One-on-one meetings and consultations with three key customer segments—energy companies, Agri-PV project developers and EPC companies, and large-scale farmland owners and farmers—were used to gather user requirements and design an integrated service system architecture for DAPV solutions. A proof of concept for this integrated system and its modules was successfully tested at the pilot sites, demonstrating technical feasibility and commercial viability, and a business case was developed to assess the potential for commercial roll-out.

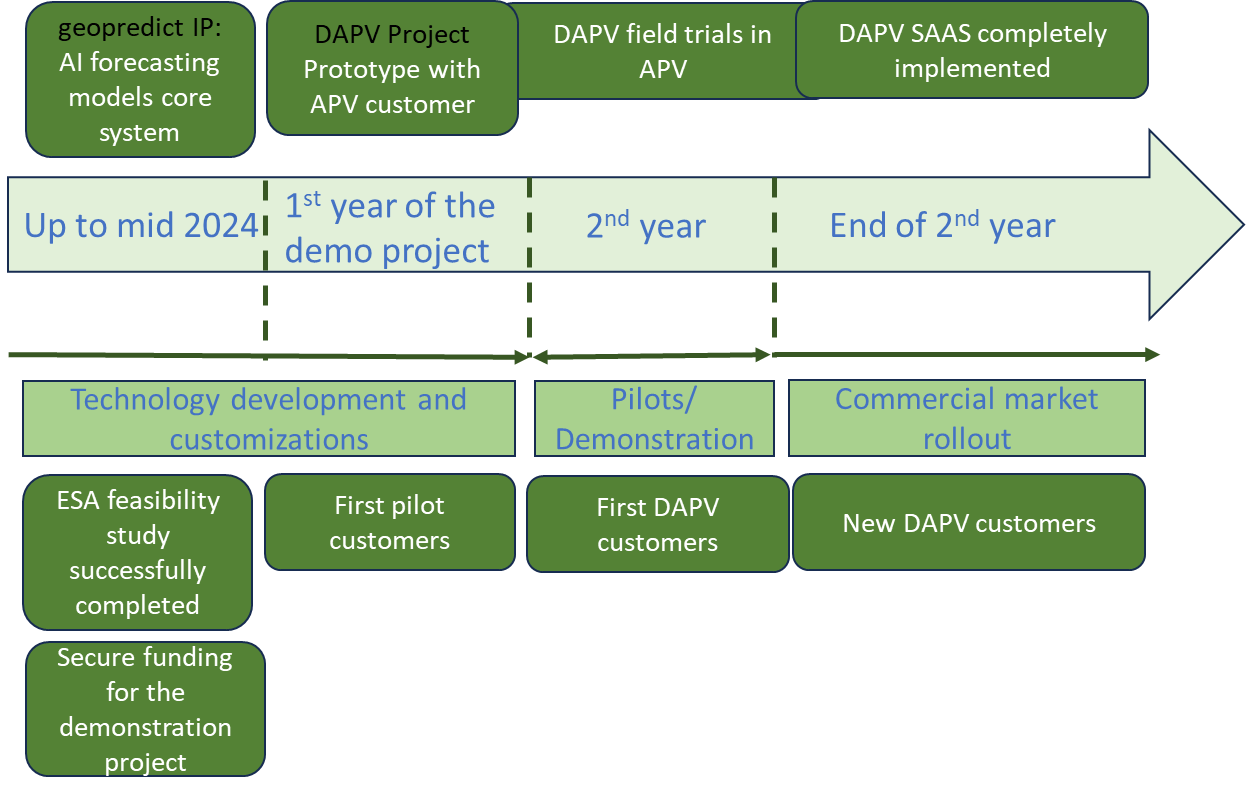

The next steps involve undertaking a demonstration project to commercially deploy these services across all Agri-PV customer segments. To fully automate Agri-PV plants, a pre-commercial service demonstration project is necessary, as illustrated in the schematic below.