Objectives of the service

The Digital Worksite solves endemic safety issues for rail maintenance teams working on active tracks.

Human errors lead to 200 serious incidents annually in the UK rail industry alone. Workers stray onto live rails. Vehicles collide with trains or overhead wires. Misplaced equipment causes derailments.

By combining precise positioning from satellites with real-time worksite visibility, the Digital Worksite provides an omnipresent safeguard. Workers and vehicles are located to centimetre-level. Danger triggers instant alerts before accidents occur.

Virtual maps designate safe zones, restricted areas and equipment sites. Dashboards give managers total command of people and assets. Guidance, notifications and analytics mitigate risk.

The project will develop and rigorously test this space-enabled solution through trials with infrastructure managers like Network Rail and contractors like Siemens.

The goal is an approved commercial system that ushers in a new era of safety for rail maintenance. Worksites will become intelligent environments that proactively protect the thousands working on active tracks across Europe.

Users and their needs

The Digital Worksite solution targets infrastructure managers and contractors carrying out railway construction and maintenance activities in the UK and Europe.

Primary users include:

-

Track workers - Need guidance to safely navigate worksites and install equipment. Challenges include loss of situational awareness and potential fatalities

-

Plant operators - Require alerts to avoid collisions and track intrusions. Challenges include accurate vehicle positioning and loss of situational awareness

-

Site managers - Require overall worksite visibility and control. Challenge is getting a unified real-time view across people, vehicles and zones.

Their needs centre on mitigating ubiquitous human errors in rail maintenance through precise positioning, instant alerts, and a complete digital worksite "twin".

The solution focuses on benefiting users in the UK initially through trials with Network Rail, Siemens, and other major contractors. It will then expand to other European markets.

Service/ system concept

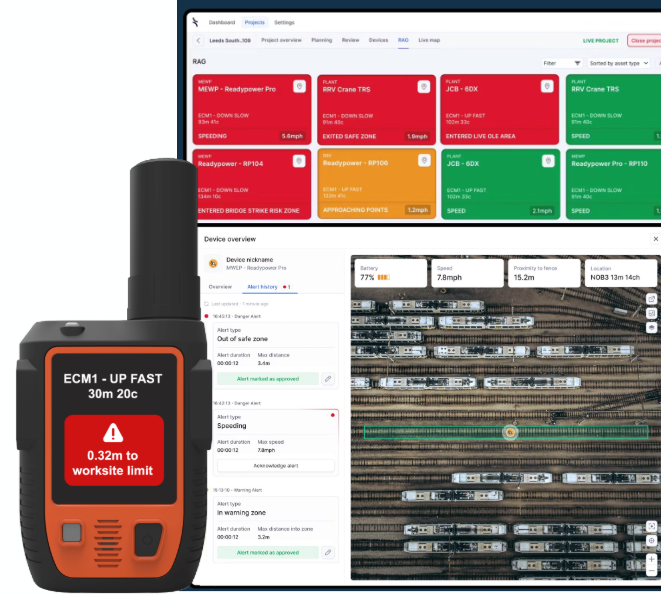

The Digital Worksite gives rail maintenance teams an unprecedented real-time view of worksite activities through precise positioning and mapping capabilities.

Workers wear a device that tracks their location down to 10cm accuracy using GNSS-RTK. Plant is outfitted with an equivalent positioning system, as well as an in-cab screen.

These locations are monitored on a mapping dashboard that incorporates high-resolution satellite imagery. Virtual boundaries designate safe zones, restricted areas, and installation points.

When workers or vehicles stray into danger, the system triggers instant alerts to their devices and the central dashboard. It guides them back to the proper area, avoiding accidents.

Managers have full command of the worksite via the dashboard. They can send navigation instructions, modify safe zones, and optimise resources.

The system architecture combines a GNSS-RTK enabled wearable devices with sensor fusion algorithms with geospatial software. This gives users an intelligent “digital twin” of the worksite that mitigates risks and prevents errors through precision tracking.

Space Added Value

The Digital Worksite uniquely combines three space assets to transform railway worksite safety and efficiency:

-

Satellite navigation enables real-time, centimetre-level accuracy (with RTK) in positioning people and assets - a level unmatched by existing solutions.High-resolution satellite imagery (50 cm or better) provides detailed overhead mapping not possible with standard consumer satellite data products. Regular refreshed views are accessible on-demand.

-

Currently, systems rely on imprecise GPS, costly ground infrastructure, or radar/lidar options unsuited to large linear worksites. Only a space-based system can provide consistent precision positioning and high-fidelity situational awareness.

By fusing robust satellite capabilities with sensor data, the Digital Worksite overcomes limitations like interference and latency that hinder current solutions. Worksites become intelligent environments with safety layers not possible previously.

This space-enabled digital twin capability represents a generational leap for rail maintenance. Workers gain an omnipresent guardian against human errors, while managers achieve complete command of their assets. The result is a revolution in worksite safety, efficiency and performance.

Current Status

The project has been completed following successful pilots with potential customers, including Siemens, CRSA, SPL Powerlines, and Network Rail, to validate the product design and system architecture. Following successful pilots, the participants have now converted into full paying customers.