Objectives of the service

MEMT is an operational efficiency digital tool that provides the information that is relevant to mining companies with just the right level of aggregation - from detailed analysis of individual factors of mining processes (mobile heavy machinery, raw material extracted, working conditions in the mine and mine organization), to the performance of mining processes and the overall operational efficiency.

Information will be offered as a service and will improve on several levels the way users currently operate, as it automates data collection from the mining site, it unifies data lakes that refer to mining processes (sensor data, image data, data from third party sources) and it automates data analysis, aggregating information based on mining-specific scenarios.

Users and their needs

MEMT mainly targets mining companies headquartered in Europe, operating small and medium size open-pit mines and quarries. The users at operation level are mine manager, foreman, machine operators. At group level there are 2 additional users: regional / technical / operational / digitalization / innovation managers and data experts. In addition to these, a secondary user segment are service providers of auxiliary mining services, that need to digitalize their processes.

Users have identified following needs:

-

to automate the monitoring and reporting of the production and material mass flow in the mines

-

to monitor and optimize equipment utilization by reducing non-productive work (idling, preparation work, unnecessary driving etc.), for reporting and controlling, to ensure proper equipment usage (train personnel and avoid machine damage, incidents etc.

-

to have a digital overview on different processes in the mine, so they can identify optimization potential (correlate excavation performance with material quality and different benches, implement road maintenance works to keep transport performance within standards, adapt mine organization (shifts, working hours, machine pairing/dispatch) to meet different production targets, correlate blasting and loading performance)

-

implement digital systems also in remote mines (with no terrestrial communication networks available)

Service/ system concept

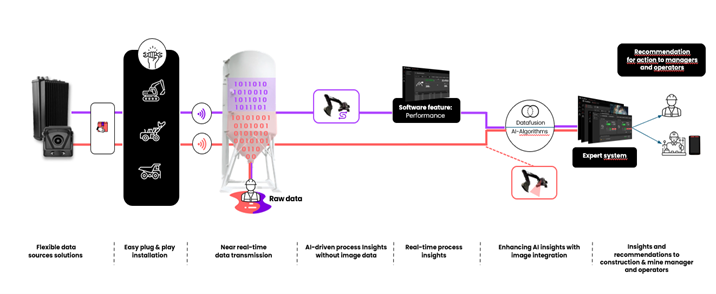

MEMT is an intelligent digital tool, based on AI, computer vision and sensor data analytics, that delivers information as a service, covering all phases from data collection and transmission, to analysis and aggregation, and finally to visualization. Integration with third party systems (data imports and exports) is also ensured.

The concept is to capture processes on site with the help of different sensors, transmit the collected data via terrestrial communication networks or via SatCom, process the data so that relevant mining events are being identified by AI algorithms and deliver the results to users via an interface.

A unique feature of MEMT relies on combining different kinds of data, so that the users get situational awareness on the mining heavy machines and also on the working environment, that they can use to optimize their operation.

Space Added Value

MEMT will use Satellite Navigation and Satellite Communication.

SatNav: location data is one of the most important data from the set – together with the timestamp they ensure the correlation between the interacting machines, the environment and the working conditions. The hardware for data collection that will be installed on the mobile heavy machines will include GNSS among other sensors (accuracy of 1,5 - 2 m is enough for our applications). GNSS is included as a base element in our products and services since 2017.

SatCom: 30% of the mines operated by one of our pilot partners have poor or no TC connectivity (“offline mines”). For providing our services to such mines, MEMT incorporates, after successfully piloting the use satellite internet, SatCom, for transmitting data between the hardware in the field and our servers. Mining customers, operating "offline" mines just needs to provide a possibility to communicate with the abaut backend by incorporating a SatCom unit. Such systems basically consist of a Wi-Fi-Router-Hub for connecting towards the mobile machinery equipped with abaut Edge sensors. This WiFi connection, together with the SatCom unit, provides the possibility of transferring all the data generated. In addition, another benefit of including the SatCom module it’s that also other devices within the mining area (e.g., laptops, sensors, smartphones, etc.) can benefit of this connectivity.

Current Status

After the completion of the project, MEMT have integrated the developed the KPIs on its innovative and integrated platform. All the results are user-friendly and easily accessible. The main functionalities developed are:

-

Development of the SatCom operational module: The integration of SatCom and Wi-Fi mesh technologies proved crucial in overcoming connectivity challenges in white zones. This advancement ensured that even remote mining operations without connectivity could benefit from seamless data integration and monitoring capabilities.

-

Fleet Performance Optimization: Automates recognition of machine activities (e.g., loading, driving, idling, preparation) to reduce non-productive work, ensure balanced workloads, and enhance equipment lifespan.

-

Production and Material Flow Monitoring: This service tracks and analyzes material movement (ore, waste, by-products) from loading to unloading areas, ensuring an accurate mass flow report and enabling better control over production processes.

-

Mine Organization and Operational Planning: Provides insights into work routines (shifts, breaks, auxiliary activities) and their impact on productivity, enabling improved daily planning and resource allocation

MEMT is now positioned for a robust commercial roll-out for the mining industry. Its SaaS pricing model, combined with flexible hardware options, makes the solution accessible to any operation but specially to the cost-sensitive operators. Thanks to its integrated solution and by delivering a scalable, user-friendly, and impactful solution, it empowers mines to achieve new levels of operational excellence and sustainability. This success underscores the transformative potential of AI-driven and connectivity-enhanced tools in fostering both economic and environmental progress in mining operations.