Objectives of the service

Within highly industrialized environments such as harbours, the road congestion and natural barriers hinder sample transportation activities while companies always demand additional efficiency to optimise costs. On top of efficiency and economical savings, the emergency of global warming, requiring actions from industrial companies, also pushes them to improve their operations and lower their CO2 emissions.

In this context, the use of drones to transport petrochemical samples can address companies’ issues and provide a safe, fast and sustainable alternative to express ground-based transportation services.

The first use of Samplifly consists in a cargo transportation service into SGS’s sample testing operations. The service of ADLC is powered by the use of cargo drones, able to carry up to 15kg up to 60km.

Users and their needs

The users of the service include industrial companies requiring express and sustainable transportation of goods. The first user of SAMPLIFLY is SGS, which is the world’s leading testing, inspection and certification company able to provide daily sampling and analysis services within petrochemical port environments. In the Port of Antwerp for instance, such testing activities are required prior to the unloading of ships. In this context, SGS is mandated to collect some samples of the cargoes, analyse them, and approve them. To deliver such a service, a key part of this process is the transport of the samples to SGS's main laboratory.

During transportation, recurring issues are faced while using existing ground-based transportation services:

-

Lack of speed

-

Lack of information

-

Lack of reliability

-

Lack of sustainability

ADLC’s transportation service was designed to meet these needs by providing a drone transportation service that is faster, more integrated and more sustainable than traditional options. The key challenge for the project is to develop a service that is technically feasible and economically viable while providing a solution that meets the specific needs of an industrial company, such as SGS in the Port of Antwerp.

Service/ system concept

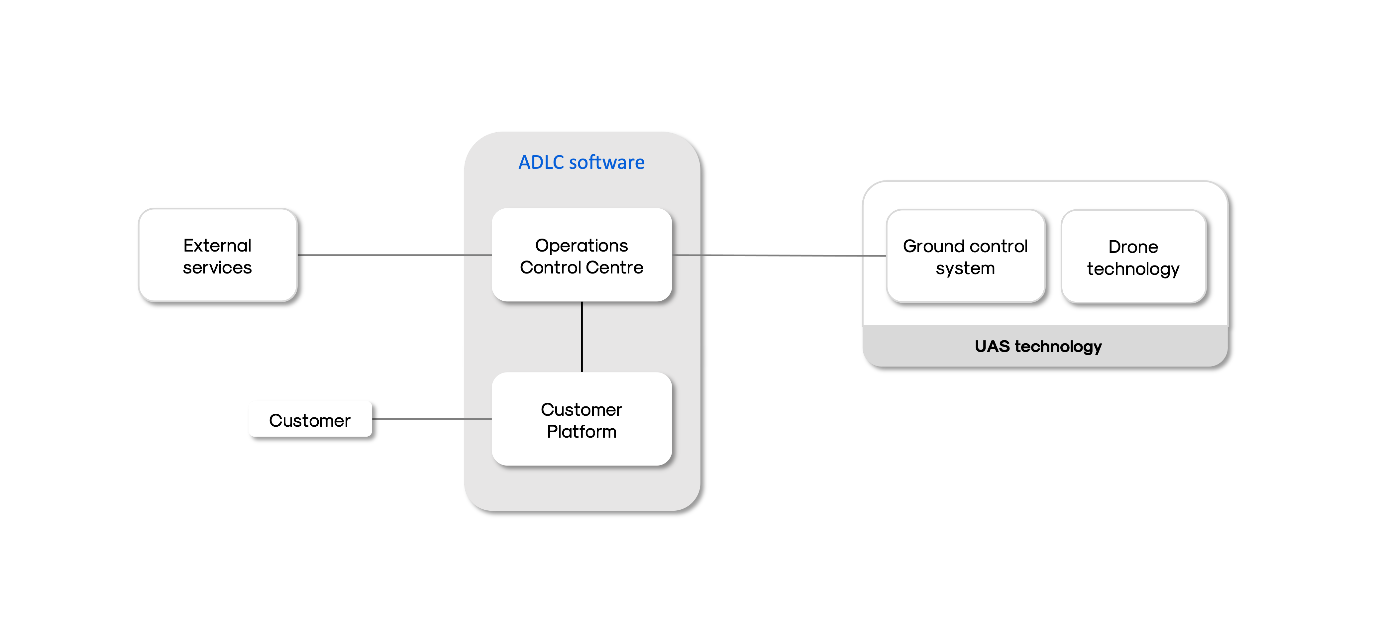

The service is provided through the use of advanced drone technology and a comprehensive software platform allowing for efficient operations. The process begins when a user places an order for delivery on ADLC's web ordering interface. This platform is designed to be user-friendly and allows for easy tracking of client orders.

At the time of sample pick-up, the drone is available at the designated take-off location, where the client can load the drone. Then, the drone flies autonomously from the take-off location to the destination through its equipped onboard computers and navigation systems. The drone is also remotely monitored by a pilot ready to trigger adequate procedures in case of incident.

The client can unload goods upon landing, and throughout the operation, the client is kept informed of the status of the order through the ordering platform.

The main building blocks of the service include:

-

Drone technology: advanced drones equipped with onboard computers and navigation systems that allow for autonomous flight.

-

Ground Control System: a system for remotely monitoring the drones during flight.

-

Operations Control Centre: software used to manage and automate ADLC’s operations.

-

Ordering platform: an easy-to-use platform for placing and tracking orders.

Space Added Value

The SAMPLIFLY service makes use of two main space assets to enable the safe flight of drones beyond the pilot's line of sight: satellite navigation and satellite imagery.

Satellite navigation, specifically Global Navigation Satellite Systems (GNSS), is used to provide the drone with precise location information, allowing it to navigate to the destination landing spot autonomously. Pilots also receive such information, which allows them to monitor operations and liaise with authorities to prevent any conflict with other aircrafts.

Satellite imagery is used to provide pilots with a detailed view of the environment in which the drone is evolving. The imagery is also used to plan the flight path, ensuring that the drone takes the safest and most efficient route to the destination.

Current Status

The SAMPLIFLY demonstration project has been successfully closed during the Final Review held on 16 May 2025. The main achievement is that ADLC now performs daily BVLOS flights, including with up to 15kg of payload using , with the PW.Orca cargo drone in the Port of Antwerp since December 2023. The flights are operated remotely from ADLC’s control center.

In June 2024, ADLC became the first company in Europe to perform BVLOS transport flights of (petro)chemical samples in a port environment and the first company worldwide to achieve it within an active controlled airspace. Since October 2024, ADLC provides a daily transportation service in the Port of Antwerp on a commercial basis.