Objectives of the service

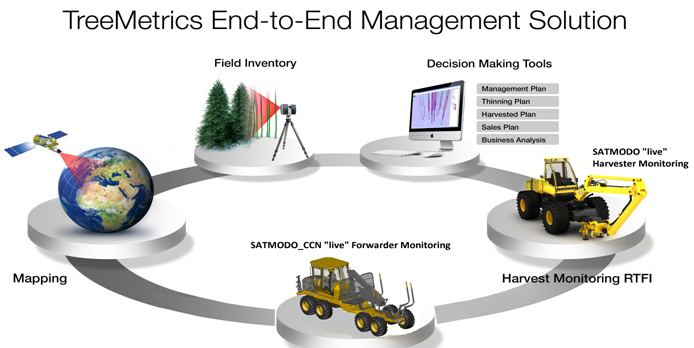

The initial project objectives were to improve the management of timber harvesting for both forest owners and harvest machine operators by improving the links with the supply chain. Forest harvest machines were monitored in real-time or near real-time using satellite and cellular networks providing information back onto a central web platform. This information helped to reduce waste and to ensure the right proportion of logs were harvested by allowing individual machines or groups of machines to be monitored. An in-vehicle device was installed in each harvest vehicle also facilitating in-vehicle mapping (boundaries & hazards) for the machine operator.

In the CCN, forest forwarding machines were monitored in real-time or near real-time using the same techniques as the harvesting machine. This information helped to increase efficiency by ensuring the flow of logs was monitored for pick up by timber trucks. It also helped to manage and ensure the right logs are forwarded to the best locations. An in-vehicle device was installed in each forwarder vehicle which also facilitated in-vehicle mapping and positioning of boundaries and hazards for the machine operator. The added security features provided timely alerts to owners/managers of interference with machines in remote locations.

Current Status

The SATMODO harvesting machine project is successfully completed.

The harvesting machine pilot stage successfully demonstrated the following,

- Monitoring of cut to length harvest machines in real-time or near-real time in order to collect “live” harvest activity data from them

- That there is a valid business case for the SATMODO system through the delivery of improved harvest management and process control

- That SATMODO performs satisfactorily in the delivery, processing and presentation of data derived from the harvesting process from any forest location using satellite and GPRS data transfer

The project extension to the forwarder machines was successfully completed in August 2014.

The Forwarding machine pilot stage successfully demonstrated the following,

- Monitoring of the Forwarding machines in real-time or near-real time in order to collect “live” forwarder activity data.

- Ability to communicate between the harvester and the forwarder. To provide locations and transfer data.

- Recorded Log types, quantity and roadside location is displayed on a web basis.

- Forwarder security to notify owner via Text and email of machine interference.

Main Achievements:

The SATMODO project has achieved most of the target objectives according to the user requirements.

The SATMODO project has three major outcomes:

(1) The development of the system enabling the operational service;

(2) The pilot of the service to the users; and

(3) The establishment of agreements with the pilot partners to use the system on a commercial basis.

The Harvester system was successfully implemented in 14 cut to length harvest machines as test vehicles for the pilot operation. SATMODO in-vehicle devices were installed in all 14 machines, linking the on-board computers in the cut-to-length (CTL) harvest machines via a local Bluetooth connection. The Pilot operations for the Harvester Machine were conducted from February 2013 to May 2013.

The system was installed in 6 Forwarder machines as test vehicles for the pilot operation. In-vehicle devices were successfully upgraded 6 CTL machines in order to reliably link the data from the cut-to-length (CTL) harvest machines with the Forwarder Machine.The Pilot operations for the Forwarder Machines were conducted from April 2014 to July 2014.

SATMODO is commercialised with the name RTFI™ (Real Time Forest Inventory); it has been successfully designed to provide an In-Vehicle-Device and online service for the efficient access and analysis of Harvesting and Forwarding data to aid in the management of the forest resource.

The adoption of new technology by the forestry industry has been very promising. Both machine owners and the Harvest managers, representing the forestry industry in Ireland, have expressed a willingness to use RTFI in the future.

The Pilot also has provided valuable feedback and results which include:

- 16% improvement in distance travelled by Forest Machines due to more effective route planning as a result of In-Vehicle-Navigation & Maps

- Faster Communication to and from the Machine 100% of the time when compared to the current system.

- 12.5% less trips necessary to the forest for harvest managers due to the ability to plan and communicate online.