Objectives of the service

Aircraft exposure to environmental factors, including ice, dust, sulphur and volcanic ash, accelerates wear of aircraft engine and airframe components, and may pose a threat to flight safety.

Unscheduled maintenance is costly to many parties in the aviation industry and causes disruption to airline operator flight schedules. SATAVIA’s mission is to enable aircraft and engine original equipment manufacturers (OEM), maintenance repair and overhaul organisations (MROs), and airline operators to minimise the cost and impact of environmental factors on aircraft and components.

Flight planning and flight operations do not incorporate environmental contaminant exposure into their flight optimisation. SATAVIA provides global forecasting capability to minimise airframe exposure in-flight, therefore reducing wear and damage on aircraft due to contaminant exposure.

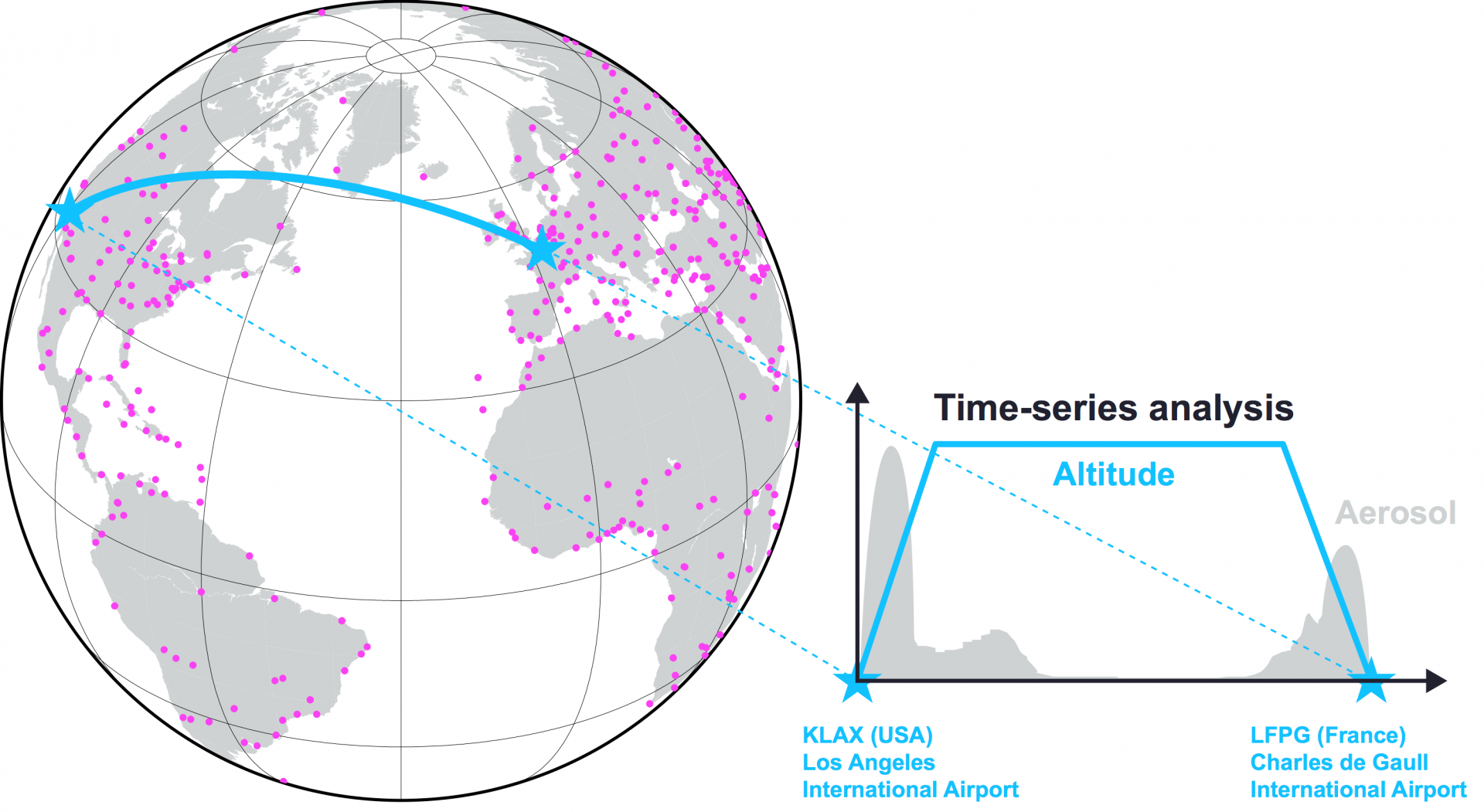

Figure: Example showing environmental contaminants experienced by an aircraft on a flight from Los Angeles to Paris, from take-off, through cruise, to landing.

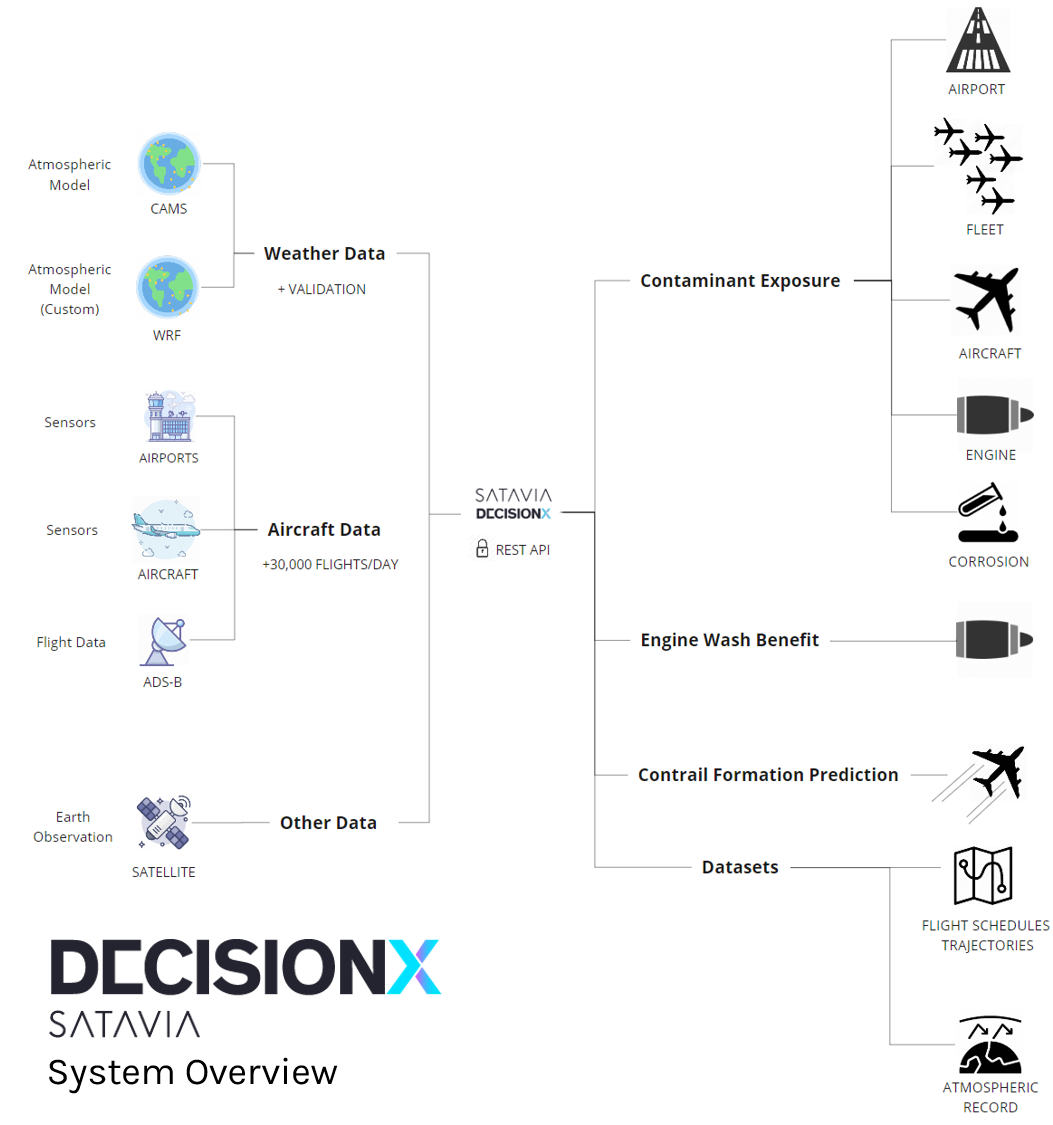

SATAVIA’s patented software platform DECISIONX™ combines technology and data from atmospheric modelling, Earth observation, maintenance records and aircraft prognostics sensor data. By aggregating disparate formats of unstructured and structured data, in both paper and digital form, DECISIONX provides environmental data in a form constructive to aviation decision making.

Users and their needs

Airlines, OEMs and MROs need to plan and schedule future maintenance tasks for each aircraft within their fleets. The timing and scope of maintenance can be significantly affected by aircraft component degradation due to exposure to damaging environmental contaminants. Premature failure (e.g. Aircraft on Ground/AOG) and unscheduled repairs can have significant, downstream impact on fleet management and operations, and orders of magnitude greater maintenance costs. In 2017 alone, unscheduled maintenance cost $20.48bn across the aviation industry, forecast to rise to $40.95bn by 2035 (source: statista.com).

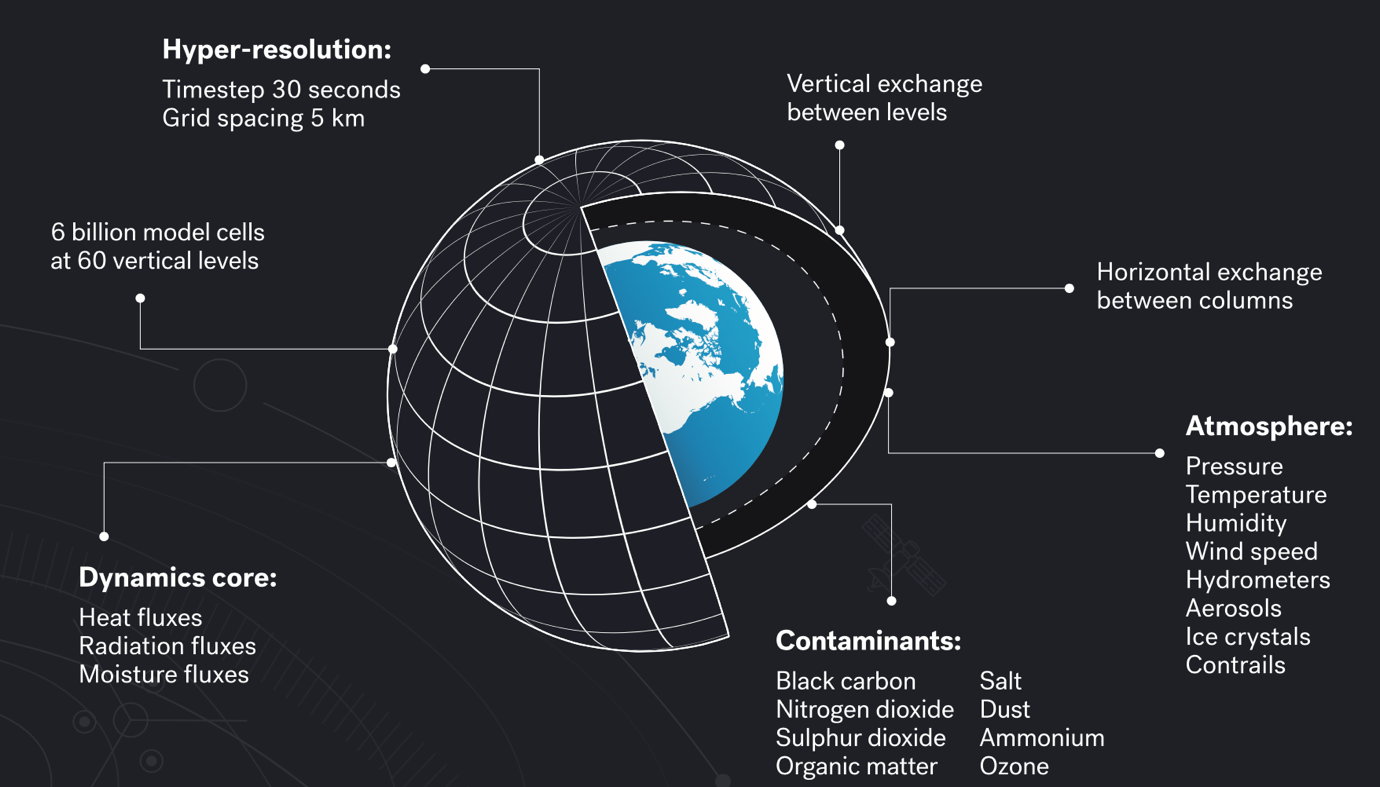

DECISIONX can perform an assessment of exposure to weather and various contaminants including dust, salt, ice, SOx, NOx, black carbon, and various other organic aerosols, for any given aircraft, flight, fleet or building over any time period from 2012 to present day. This is made possible by maintaining a continuous historic record of atmospheric contaminants in three dimensional space, over time.

The aAbove pictures shows: sand-coated high pressure turbine blades. DECISIONX can quantify an individual engine, aircraft or fleet’s exposure to aerosols such as dust over time.

Uniquely, DECISIONX support allows users to schedule preventative maintenance tasks for each aircraft in their fleet based on per-aircraft and/or per-engine contaminant exposure analysis, meeting key maintenance decision-making requirements of quality, accuracy and timeliness of data provision.

By ingesting condition reports and details of maintenance interventions, DECISIONX can also make forward recommendations of maintenance tasks and costs, including threshold-based alerting. This capability is highly valuable to those responsible for financial management of aviation assets (e.g. lessors, airlines and OEMs using the Power-by-the-Hour engine rental model), furnishing vital information on current aircraft value and future financial costs of maintenance and reparation.

To minimise degradation of aircraft value, DECISIONX allows flight operations and flight planning departments to incorporate environmental contaminant exposure into their flight optimisation. SATAVIA provides global forecasting capability to minimise airframe exposure in-flight, therefore reducing wear and damage on aircraft due to contaminant exposure.

Service/ system concept

DECISIONX from SATAVIA integrates an array of data sources including environmental observation (in particular satellite and observation data), climate models, and third-party datasets.

DECISIONX processes global flight data to produced cleaned trajectories and estimated flight schedules for up to 100,000 flights per day. Flight data is then combined with atmospheric modelling of four-dimensional (4D) datasets that includes weather (e.g. ice, temperature, humidity) and contaminants (e.g. salt, black carbon, SOx, NOx, and various other organic aerosols). An exposure analysis can then be performed for a given flight trajectory, group of flights, or stationary asset.

Above:The picture presented above shows how SATAVIA’s atmospheric modelling provides a continuous record of weather and contaminants from 2012 to present day. Aircraft trajectories are plotted through these four-dimensional data to quantify exposure.

The DECISIONX platform is accessed via a secure API, facilitating rapid integration into customer 3rd party systems.

Space Added Value

Space assets involved include Earth Observation (EO) services such as Meteosat and Sentinel satellites, providing input data for global climate models and numerical weather prediction models. In addition, SATAVIA utilises customer-provided aeronautical satellite data communications and the Spire constellation for location data of aviation assets via ADS-B tracking data.

Current Status

The Pilot Trial of the DECISIONX system took place between 1 December 2021 and 6 January 2022. SATAVIA quantified expected improvements to aero engine Time-on-Wing (TOW) and engine wash cost benefit via improved prediction of Exhaust Gas Temperature Hot Day Margin (EGTHDM) Degradation rate. SATAVIA analysed satellite Automatic Dependent Surveillance – Broadcast (ADS-B) data and environmental contaminant exposure to improve the prediction of EGTHDM.

The Project Final Review established that inclusion of base environmental parameters (such as those provided by DECISIONX) enhanced engine performance modelling accuracy by 49%. In addition, DECISIONX data allowed for a 5% increase in EGTHDM predictability and increased interpretability of factors influencing engine performance degradation. Increased prediction accuracy allowed for a 10% increase in the number of cycles between engine washes, and across multiple engine washes between shop visits, a 7.6% increase in the overall TOW – equating to an estimated annual saving of $55k per aircraft.

The next steps:

SATAVIA will now carry out a contract change notice, with the aim of enabling airlines to be smarter and greener through reducing their non-CO2 footprint. SATAVIA’s DECISIONX platform utilises the technology stack and atmospheric modelling developed during the DECISIONX project to a forecast contrail formation, prevent the formation of contrails, quantify resulting climate benefit, and convert into carbon equivalent credits for trading in a new market worth in excess of $18.3bn per year (CBI figures). For users (i.e. airlines and other aircraft operators), SATAVIA contrail avoidance technology reduces the climate impact of necessary flight operations, generating consumer-facing green credentials and – in future – commercially beneficial offset credits. SATAVIA’s high impact contrail prevention technology has the potential to eliminate up to 60% of aviation’s impact on climate (Lee et al, 2021).